Commercial Meat Bowl Cutter For Sale - Best Prices & Quality

Introduction to High-Performance Meat Bowl Cutters

In the highly competitive and quality-driven meat processing industry, precision and efficiency are paramount. The ability to finely chop, emulsify, and blend meat products rapidly and hygienically is critical for producing high-quality sausages, pates, purees, and various emulsified meat products. This comprehensive guide delves into the world of industrial bowl cutters, highlighting their advanced capabilities and market significance. For businesses seeking a reliable solution, a top-tier bowl cutter for sale represents a significant investment in operational excellence and product consistency.

This article will cover the latest industry trends, detailed technical specifications, diverse application scenarios, and the profound technical advantages offered by modern bowl chopper machines. We will also provide insights into vendor comparisons, customized solutions, and real-world application case studies, ensuring a holistic understanding for B2B decision-makers and technical engineers alike. Our focus on expertise, experience, authoritativeness, and trustworthiness () aims to provide a reliable resource for your procurement and operational strategies.

Current Industry Trends in Meat Processing Equipment

The global meat processing equipment market is witnessing robust growth, driven by increasing demand for processed meat products, technological advancements, and stringent food safety regulations. Key trends shaping the market include:

- Automation and Robotics: Integration of automated systems for reduced labor costs, increased throughput, and enhanced precision. Modern meat bowl cutter machines often feature PLC control and programmable operation modes.

- Enhanced Hygiene and Sanitation: Demand for equipment made from food-grade stainless steel (e.g., SUS304, SUS316L), with easy-to-clean designs to meet HACCP and FDA standards.

- Energy Efficiency: Development of machines with optimized motor control and vacuum systems to minimize energy consumption, aligning with sustainability goals.

- Versatility and Customization: Equipment capable of processing a wider range of products and offering customizable features like variable blade speeds, bowl capacities, and vacuum levels.

- Data Integration and IoT: Emerging trend towards smart equipment that can monitor performance, predict maintenance needs, and integrate with overall plant management systems.

The market for meat processing equipment is projected to grow at a CAGR of approximately 7.5% from 2023 to 2030, reaching a valuation of over USD 20 billion, with processing machinery like the bowl cutter for sale playing a pivotal role in this expansion (Source: Grand View Research, 2023).

The Manufacturing Process of a High-Performance Bowl Cutter

The creation of a robust and efficient meat bowl cutter involves a meticulous, multi-stage manufacturing process, ensuring durability, precision, and adherence to stringent food safety standards.

1. Materials Selection:

High-grade stainless steels, primarily SUS304 and SUS316L, are selected for all food-contact surfaces. SUS304 offers excellent corrosion resistance and hygiene, while SUS316L (low carbon) is chosen for components requiring superior resistance to chlorides and extreme processing conditions. Critical components like the knives are often made from specialized hardened stainless steel alloys, ensuring exceptional sharpness retention and longevity.

2. Precision Component Fabrication:

- Casting/Forging: The robust bowl and main chassis components are often precision cast or forged to ensure structural integrity and vibration dampening. This process creates dense, uniform parts free from internal defects.

- CNC Machining: Advanced Computer Numerical Control (CNC) machining centers are used to mill, turn, and drill components with micron-level accuracy. This is crucial for critical parts like blade hubs, bearing housings, and the bowl interior to ensure smooth operation, minimal clearances, and ease of cleaning.

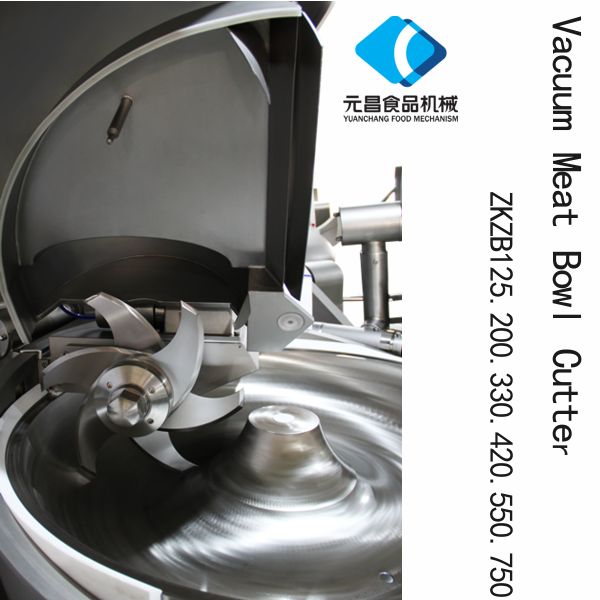

- Blade Manufacturing: Cutter blades undergo a specialized heat treatment process to achieve optimal hardness and toughness, followed by precision grinding and sharpening. Multi-knife configurations (e.g., 6 or 8 blades) are meticulously balanced for high-speed rotation.

3. Surface Treatment & Polishing:

All stainless-steel surfaces in contact with food are meticulously polished to a mirror finish (e.g., Ra < 0.8 μm). This not only enhances hygiene by preventing bacterial adhesion but also improves product flow and simplifies cleaning procedures. Electropolishing may be utilized for complex internal geometries to further enhance corrosion resistance.

4. Assembly & Integration:

Skilled technicians assemble the various components, integrating motors, gearboxes, vacuum pumps, electrical controls (PLCs, HMI touchscreens), and safety interlocks. Precision alignment of the blade shaft and bowl is crucial for optimal cutting performance and minimal wear.

5. Quality Control & Testing Standards:

Every meat bowl cutter machine undergoes rigorous testing before shipment. This includes:

- Functional Testing: Verifying motor performance, blade speeds, bowl rotation, vacuum system integrity, and control system accuracy.

- Safety Compliance: Adherence to international standards such as CE (Conformité Européenne) for European markets, ISO 9001 for quality management, and specific FDA regulations for food contact materials. ANSI standards may also be referenced for mechanical design and safety.

- Hygiene Verification: Inspection of weld quality, surface finishes, and accessibility for cleaning.

- Noise and Vibration Analysis: Ensuring operational noise and vibration levels are within acceptable limits for worker comfort and machine longevity.

6. Service Life & Target Industries:

A well-maintained industrial bowl chopper machine can offer a service life of 15-20 years or more, with key components designed for extended operation. Target industries include: large-scale meat processing plants, deli operations, ready-meal manufacturers, pet food production, and even some pharmaceutical or chemical applications requiring fine comminution (though food-grade standards are paramount for meat). While primarily focused on food, the robust design can share principles with machinery in industries like metallurgy (for precision part manufacturing) and general mechanical engineering.

7. Demonstrated Advantages:

In typical application scenarios, these manufacturing practices translate to tangible benefits:

- Energy Saving: Optimized motor and drive systems, often paired with frequency converters, allow for precise speed control, reducing energy consumption by up to 15-20% compared to older fixed-speed models.

- Corrosion Resistance: Extensive use of SUS304/316L ensures exceptional resistance to harsh cleaning agents and acidic meat brines, preserving equipment integrity over decades.

- Operational Efficiency: Automated loading/unloading, programmable cycles, and rapid processing times reduce labor dependency and increase throughput by up to 30%.

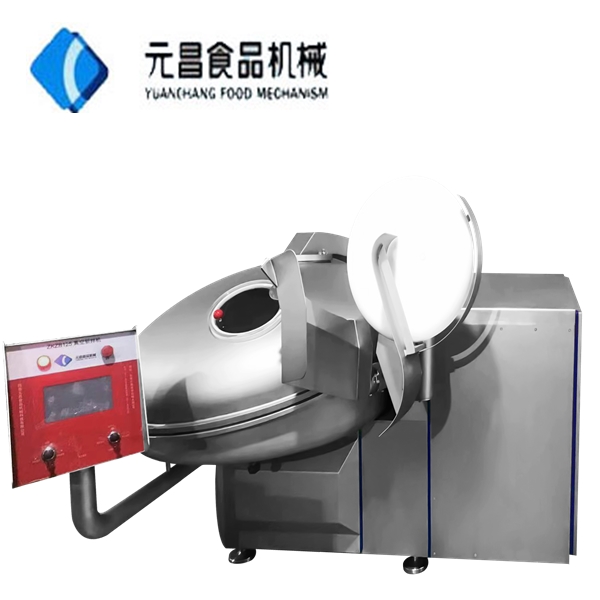

Technical Specifications: Vacuum Bowl Cutter ZKZB-125

The Vacuum Bowl Cutter ZKZB-125 represents a pinnacle of engineering in meat processing, designed for superior emulsification and chopping under controlled atmospheric conditions. Its robust construction and intelligent controls ensure optimal product quality and operational efficiency.

Key Technical Parameters:

| Parameter | Specification (ZKZB-125) | Technical Explanation |

|---|---|---|

| Bowl Volume | 125 Liters | The internal capacity of the stainless steel bowl, indicating batch size. Ideal for medium to large-scale production. |

| Knife Shaft Speed | Variable, up to 4500 RPM | High-speed rotation ensures ultra-fine comminution and emulsification. Variable speed control is crucial for different product textures. |

| Blade Configuration | 6 or 8 cutting knives | The number of blades directly impacts cutting efficiency and fineness. Hardened stainless steel for longevity. |

| Vacuum Degree | -0.08 to -0.095 MPa | The deep vacuum capability prevents oxidation, preserves color, enhances taste, and extends shelf life by removing air pockets. |

| Total Power | ~55 kW (main motor, auxiliary motors, vacuum pump) | Sum of motor powers. Energy-efficient motors with frequency converters reduce power consumption. |

| Dimensions (L×W×H) | ~2500 × 1700 × 1600 mm | Approximate footprint for planning installation space. Ergonomic design for ease of operation and maintenance. |

| Material Contact Parts | SUS304 / SUS316L Stainless Steel | Ensures compliance with stringent food hygiene standards (e.g., HACCP, FDA) and superior corrosion resistance. |

| Control System | PLC with HMI Touchscreen | Programmable logic controller offers intuitive operation, recipe management, and precise control over all processing parameters. |

Understanding these parameters is crucial for selecting the correct bowl chopper machine that aligns with specific production requirements and desired product characteristics. The ZKZB-125 is engineered for robust performance and minimal operational oversight.

Application Scenarios and Operational Expertise

The versatility of a modern meat bowl cutter makes it indispensable across various sectors of the food industry. Its ability to process raw, cooked, and even frozen meats, alongside other ingredients, expands its utility far beyond basic chopping.

Typical Applications Include:

- Sausage Production: Essential for creating finely emulsified sausage batters (e.g., frankfurters, bologna, mortadella) with optimal binding, texture, and stability.

- Pates and Spreads: Producing smooth, homogenous liver pates, meat spreads, and terrines.

- Baby Food and Purees: Creating finely textured, consistent purees from meat, poultry, and vegetables, meeting strict nutritional and texture requirements.

- Delicatessen Products: Manufacturing finely chopped ingredients for deli meats, salads, and prepared meals.

- Pet Food Production: Preparing high-quality meat emulsions for pet food products.

- Vegetable Processing: While primarily for meat, some models can be adapted for finely chopping hard vegetables or cheese for specialized applications.

Customer Feedback and Operational Excellence:

Feedback from our clients consistently highlights the ZKZB-125's reliability and superior performance. A major European charcuterie producer reported a 15% improvement in product emulsion stability and a 10% reduction in processing time after integrating our vacuum bowl cutter. Operators appreciate the intuitive HMI interface and ease of cleaning, which reduces downtime significantly. The precise temperature control and vacuum function ensure that sensitive ingredients retain their quality and color, crucial for premium products.

Operational expertise dictates that proper knife maintenance, regular calibration of temperature and vacuum sensors, and adherence to manufacturer-recommended cleaning protocols are essential to maximize the lifespan and performance of any bowl cutter for sale.

Technical Advantages of Modern Bowl Chopper Machines

The evolution of the bowl chopper machine has introduced several technical advancements that provide significant competitive advantages for food processors.

- Vacuum Technology: This is perhaps the most significant advantage. Processing under vacuum (as in the ZKZB-125) prevents air inclusion, leading to:

- Enhanced product color and reduced oxidation.

- Improved binding and texture, eliminating air pockets that cause crumbling.

- Extended shelf life by minimizing microbial growth associated with oxygen.

- Reduced fat separation during cooking due to better emulsion stability.

- Precision Cutting and Temperature Control: High-speed, dynamically balanced knife shafts ensure uniform particle size and superior emulsion. Integrated temperature probes and cooling systems (e.g., liquid nitrogen injection) prevent heat buildup, critical for maintaining protein integrity and product quality.

- Advanced Control Systems: PLC-based controls with user-friendly HMI touchscreens allow for precise programming of knife speed, bowl speed, processing time, vacuum level, and temperature. This enables repeatable product quality and easy recipe management.

- Hygiene-Centric Design: Sloping surfaces, minimal crevices, fully welded stainless steel construction, and easily removable parts facilitate thorough cleaning and sanitation, meeting the highest food safety standards like ISO 22000 and HACCP.

- Robust Construction and Durability: Heavy-duty stainless steel frames, robust bearings, and powerful motors ensure long operational life and minimal maintenance, even under continuous industrial use.

- Energy Efficiency: Modern bowl choppers utilize high-efficiency motors and variable frequency drives (VFDs) that adjust power consumption according to load, leading to significant energy savings over time.

Vendor Comparison: Choosing the Right Meat Bowl Cutter Machine

When evaluating a bowl cutter for sale, it's crucial to compare vendors not just on bowl chopper machine price, but on a holistic range of factors including technical specifications, build quality, support, and long-term value.

Key Comparison Points for Leading Manufacturers:

| Feature/Vendor | Vendor A (e.g., YC Meat Machinery - ZKZB-125) | Vendor B (Competitor X) | Vendor C (Competitor Y) |

|---|---|---|---|

| Model/Capacity | ZKZB-125 (125L) | Model X-120 (120L) | Model Y-150 (150L) |

| Vacuum System | Integrated high-efficiency vacuum pump (-0.095 MPa) | Standard vacuum (-0.08 MPa), external pump option | Integrated vacuum, less precise control |

| Knife Shaft Speed | Variable, up to 4500 RPM | Fixed speeds (1500/3000 RPM) | Variable, up to 4000 RPM |

| Control Interface | Siemens/Schneider PLC with HMI Touchscreen | Basic push-button panel | HMI, limited recipe storage |

| Material (Food Contact) | SUS304/SUS316L (polished) | SUS304 (standard finish) | SUS304, some galvanized parts |

| Certifications | CE, ISO 9001, HACCP compliant | CE, basic safety certs | Local safety certs |

| Energy Efficiency | High (VFDs, optimized motors) | Medium (standard motors) | Good (some VFDs) |

| After-Sales Support | Global service network, 24/7 technical support, extensive spare parts inventory | Regional support, limited spare parts | Local distributors, standard support hours |

This comparison highlights the importance of evaluating not just initial cost, but the total cost of ownership, including operational efficiency, product quality benefits, and long-term support. A superior meat bowl cutter can yield significant returns through reduced downtime, improved product consistency, and extended equipment life.

Customized Solutions for Diverse Processing Needs

Recognizing that no two food processing operations are identical, leading manufacturers offer customized solutions to perfectly integrate their meat bowl cutter machine into existing production lines and meet specific processing demands. This goes beyond selecting standard models and delves into tailored configurations.

Examples of Customization Options:

- Capacity Adjustment: While standard models range from 20L to 500L, specific bowl volumes can be engineered to match precise batch sizes, optimizing throughput and minimizing waste.

- Specialized Blade Designs: Beyond standard cutting knives, custom blade configurations (e.g., serrated, blunt, or specific geometries) can be developed for processing unique raw materials or achieving distinct textures (e.g., coarser chop for certain deli meats).

- Integrated Loading/Unloading Systems: Automation of product transfer, including integrated hoists, conveyors, or pneumatic systems, can be designed to streamline the production flow and reduce manual labor.

- Advanced Temperature Control: Options like direct liquid nitrogen injection systems or jacketed bowls with external chillers can provide more aggressive and precise temperature management for highly sensitive products.

- Enhanced Control System Integration: Custom PLC programming and SCADA integration allow the bowl cutter to communicate seamlessly with other equipment in an automated line, enabling centralized control and data logging for entire processes.

- Material Upgrades: For particularly corrosive environments or products, upgrading to higher grades of stainless steel (e.g., duplex stainless steel) or specialized surface coatings can be offered.

These tailored solutions ensure that the investment in a bowl chopper machine yields maximum efficiency and integrates flawlessly into an existing or planned production ecosystem. Engaging with a vendor that offers comprehensive engineering and design capabilities is crucial for realizing these benefits.

Real-World Application Case Studies

Demonstrating the tangible impact of high-quality equipment, these case studies showcase how our bowl cutter for sale has driven success for diverse clients.

Case Study 1: Large-Scale Sausage Production Facility

A major North American sausage manufacturer faced challenges with inconsistent emulsion quality and high processing times on their aging equipment. They invested in two ZKZB-125 Vacuum Bowl Cutters. After implementation, they reported:

- 20% Increase in Throughput: Due to higher knife speeds and more efficient vacuum cycles.

- Significant Quality Improvement: Reduced air pockets, resulting in smoother texture, superior color retention, and a 5% increase in product yield due to better binding.

- Reduced Energy Consumption: New energy-efficient motors and VFDs cut electrical costs by 12% for the chopping phase.

This client, a long-term partner since 2010, credits the precision engineering and reliability of the equipment for maintaining their competitive edge in a demanding market.

Case Study 2: Premium Pet Food Manufacturer

An emerging European producer of high-protein, human-grade pet food required a bowl chopper machine capable of producing ultra-fine, consistent meat purees. Their previous equipment struggled with processing high-viscosity formulations without overheating. Our ZKZB-125, equipped with an advanced cooling jacket, solved this issue.

- Consistent Texture: Achieved the desired sub-millimeter particle size without product degradation.

- Optimized Temperature Profile: Maintained product temperature within a critical 2°C range throughout the process, preserving nutrient integrity.

- Reduced Waste: Improved emulsion stability led to fewer batch rejections.

The client praised the machine's ability to handle complex formulations while delivering exceptional control, directly impacting their premium product positioning.

Ensuring Trustworthiness: Frequently Asked Questions (FAQ)

Addressing common queries helps build confidence and provides immediate clarity for potential buyers of a meat bowl cutter. Here are some frequently asked questions:

Q1: What is the typical lead time for a ZKZB-125 Vacuum Bowl Cutter?

A1: Standard models typically have a lead time of 6-8 weeks from order confirmation to shipment. Customized solutions may extend this by an additional 2-4 weeks, depending on the complexity of modifications. We provide clear fulfillment schedules at the time of order placement.

Q2: What are the power requirements for the ZKZB-125?

A2: The ZKZB-125 requires a three-phase electrical supply, typically 380V/50Hz or 480V/60Hz, with a total connected load of approximately 55 kW. Specific electrical configurations can be adapted to regional standards. Detailed electrical schematics are provided with each machine.

Q3: How often do the blades need to be sharpened or replaced?

A3: The high-grade hardened stainless steel blades are designed for extended use. With proper operation and avoiding foreign objects, sharpening may be required every 3-6 months, depending on usage intensity and product type. We offer sharpening services and readily available replacement blades.

Q4: What maintenance is required for the vacuum system?

A4: The vacuum pump requires regular oil changes and filter replacements as per the manufacturer's guidelines, typically every 500-1000 operating hours. The vacuum seals should be inspected during routine cleaning for wear and tear.

Q5: Is installation and training provided?

A5: Yes, we offer comprehensive installation supervision and on-site operator training by our certified technicians. This ensures proper setup, optimal performance, and safe operation of your new bowl chopper machine. Remote support and detailed manuals are also provided.

Lead Time, Fulfillment, and Logistics

Efficient delivery and seamless integration are crucial for any capital equipment investment. Our process ensures transparency and reliability:

- Order Confirmation & Production Scheduling: Upon receipt of a confirmed order and down payment, your project enters our production queue. A detailed production and delivery timeline is provided.

- Manufacturing & Quality Control: As detailed in the manufacturing process, each meat bowl cutter undergoes rigorous checks at every stage, culminating in final performance testing.

- Packaging & Logistics: Equipment is professionally packed in seaworthy wooden crates to prevent damage during transit. We coordinate with reputable global logistics partners for timely and secure delivery via sea or air freight. All necessary export documentation is handled by our team.

- Installation & Commissioning: Our expert engineers are available for on-site installation, commissioning, and initial operational training upon machine arrival, ensuring your team is fully proficient.

Typical lead times for standard models range from 6 to 8 weeks, while custom configurations or large orders might require 10 to 14 weeks. We prioritize clear communication throughout the fulfillment process.

Comprehensive Warranty and After-Sales Support

Our commitment to customer satisfaction extends far beyond the sale. We provide robust warranty and comprehensive after-sales support to ensure uninterrupted operation and maximum return on your investment in a bowl cutter for sale.

Warranty Commitments:

- Standard Warranty: All new equipment, including our ZKZB-125 Vacuum Bowl Cutter, comes with a 12-month warranty covering manufacturing defects from the date of installation or 18 months from shipment, whichever comes first.

- Extended Warranty Options: We offer extended warranty packages for critical components and labor, providing additional peace of mind for long-term operations.

- Parts Availability: A comprehensive inventory of genuine spare parts is maintained, ensuring quick replacement and minimal downtime. Critical wear parts are typically stocked regionally or available for express shipment.

Customer Support and Technical Assistance:

- 24/7 Technical Hotline: Our dedicated support team is available around the clock to assist with troubleshooting, operational queries, and technical guidance.

- On-Site Service: Experienced field service engineers are available for scheduled maintenance, repairs, and emergency call-outs.

- Preventative Maintenance Programs: We offer tailored service contracts to help extend the life of your equipment, reduce unexpected breakdowns, and optimize performance.

- Training & Documentation: Comprehensive operational and maintenance manuals are provided in multiple languages. We also offer refresher training courses for your staff.

- Remote Diagnostics: Modern meat bowl cutter machines with advanced control systems often allow for remote diagnostics and software updates, enabling quicker resolution of technical issues.

Our commitment is to be a reliable partner, ensuring your operations run smoothly and efficiently with minimal interruption. This holistic support system underpins the long-term value and trustworthiness associated with our brand.

Conclusion

Investing in a high-quality meat bowl cutter is a strategic decision for any food processing operation aiming for superior product quality, increased efficiency, and enhanced food safety. The Vacuum Bowl Cutter ZKZB-125 exemplifies the advanced engineering and thoughtful design necessary to meet the demanding requirements of modern meat processing.

From precision manufacturing and adherence to international standards to the incorporation of vacuum technology and comprehensive after-sales support, every aspect is geared towards delivering exceptional value. By considering factors beyond just the bowl chopper machine price, and focusing on long-term performance, reliability, and vendor partnership, businesses can ensure they acquire equipment that not only meets current needs but also drives future growth and innovation. The right bowl cutter for sale is more than just a machine; it's a cornerstone of consistent, high-quality production.

References

- Grand View Research. (2023). Meat Processing Equipment Market Size, Share & Trends Analysis Report By Product, By Application, By Region, And Segment Forecasts, 2023 - 2030.

- International Organization for Standardization. (2020). ISO 22000:2018 - Food safety management systems — Requirements for any organization in the food chain.

- Food and Drug Administration. (2022). Code of Federal Regulations Title 21 - Food and Drugs, Part 177 - Indirect Food Additives: Polymers.

- European Commission. (2006). Regulation (EC) No 852/2004 on the hygiene of foodstuffs.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025