Commercial Bowl Cutter For Sale - Best Meat Chopper Machine

Navigating the Market for High-Performance Bowl Cutters

In the highly competitive food processing industry, achieving precise product consistency and optimal texture is paramount. For businesses seeking to enhance their production capabilities, the search for a reliable bowl cutter for sale represents a critical investment. These indispensable machines, often referred to as meat bowl cutter or bowl chopper machine, are engineered to finely chop, emulsify, and mix ingredients under controlled conditions, thereby defining the quality of a wide array of products from sausages and pates to vegetarian spreads and baby food.

The demand for advanced food processing machinery is driven by global trends emphasizing automation, hygiene, and product versatility. According to recent market analyses, the global food processing equipment market is projected to reach over $100 billion by 2027, with a significant portion attributed to meat and poultry processing machinery. This growth underscores the increasing need for efficient and sophisticated equipment capable of meeting stringent safety standards and diverse consumer preferences. Companies are constantly seeking meat bowl cutter machine solutions that offer superior performance, energy efficiency, and low maintenance.

Modern bowl cutters, particularly vacuum models, address key industry challenges by minimizing air pockets in the final product, which extends shelf life, enhances color stability, and improves overall texture. Understanding the intricate technical specifications, application scenarios, and potential for customized solutions is crucial for making an informed purchasing decision in this specialized sector. This article delves into the core aspects of these machines, offering insights valuable to B2B decision-makers and technical personnel.

Manufacturing Excellence: The Journey of a Premium Bowl Cutter

The manufacturing process of a high-performance bowl cutter for sale is a testament to precision engineering and material science, ensuring the durability, hygiene, and efficiency required in demanding food production environments.

Key Stages of Production:

- ✓ Material Selection: Only food-grade stainless steel (typically SUS304 or SUS316L) is utilized for all components in contact with food. This choice ensures exceptional corrosion resistance, ease of cleaning, and compliance with global food safety regulations such as FDA and HACCP. Knife blades are crafted from specialized, high-alloy steels, selected for their edge retention and hardness.

- ✓ Component Fabrication: Advanced techniques like precision laser cutting, CNC bending, and automated welding are employed to form the bowl, machine chassis, and protective covers. These processes guarantee tight tolerances and robust construction.

- ✓ Knife and Shaft Production: The heart of the bowl cutter, the knife assembly, undergoes rigorous manufacturing. Blades are forged, then precisely ground and hardened to achieve optimal sharpness and longevity. The knife shaft and main drive shaft are produced via multi-axis CNC machining, ensuring perfect alignment and minimal vibration even at high rotational speeds (e.g., up to 4800 RPM). Dynamic balancing procedures are critical at this stage.

- ✓ Precision Assembly: Mechanical, electrical, and vacuum components are meticulously assembled in controlled environments. This includes the integration of high-precision bearings, robust motor systems, and sophisticated control panels.

- ✓ Surface Treatment: All food-contact surfaces undergo extensive polishing and passivation. This treatment creates an ultra-smooth finish that prevents bacterial adhesion and enhances corrosion resistance, facilitating thorough cleaning and sanitation.

Rigorous Testing and Quality Assurance:

Each unit undergoes a comprehensive suite of tests to ensure compliance with international standards and guaranteed performance:

- ✓ Operational Performance Tests: Verification of knife speed, bowl rotation speed, vacuum integrity (for vacuum models), temperature control accuracy, and overall emulsification efficiency.

- ✓ Safety & Compliance: Adherence to CE standards, ISO 9001 quality management, and electrical safety protocols (e.g., IEC standards). All safety interlocks and emergency stop functions are thoroughly checked.

- ✓ Durability & Service Life: Machines are designed for an average service life of 10-15 years, provided regular maintenance is performed. Load testing and continuous operation simulations validate component robustness.

High-precision engineering ensures robust and hygienic performance.

Target Industries & Operational Advantages:

These sophisticated machines are essential across a spectrum of food processing sectors:

- → Meat Processing: Production of sausages, frankfurters, bologna, pates, and fine meat emulsions.

- → Poultry & Fish Processing: Creation of fish balls, surimi, and poultry-based products.

- → Plant-Based Foods: Emulsifying and blending ingredients for vegetarian and vegan sausages, meat alternatives, and spreads.

- → Pet Food Manufacturing: Producing high-quality, consistent pet food emulsions.

- → Dairy & Confectionery: Fine processing for certain dairy-based desserts or confectionery fillings.

The core advantages in these scenarios include superior emulsification stability, precise texture and particle size control, enhanced hygiene (easy cleaning, food-grade materials), energy-efficient motors, advanced safety features, and increased product shelf life (especially with vacuum models).

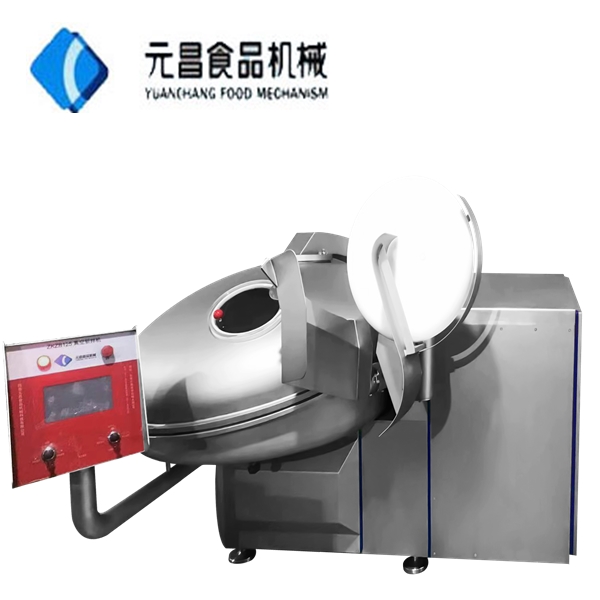

Technical Specifications: Vacuum Bowl Cutter ZKZB-125

The Vacuum bowl cutter ZKZB-125 represents a pinnacle of engineering in the food processing industry, specifically designed to meet the rigorous demands for quality, hygiene, and efficiency. Its advanced features ensure superior product output, making it a prime consideration for any enterprise looking for a high-capacity meat bowl cutter.

The ZKZB-125 is designed with an emphasis on ergonomic operation and easy maintenance. Its robust construction minimizes vibration, ensuring a stable processing environment, even during intensive operations. The incorporation of a PLC (Programmable Logic Controller) with a touch screen HMI (Human-Machine Interface) allows for precise control over processing parameters, enabling operators to achieve consistent product quality with minimal effort. The variable knife and bowl speeds are crucial for adapting to different product requirements, from coarse chopping to ultra-fine emulsification.

Application Scenarios and Operational Experience

The versatility of a modern meat bowl cutter machine extends across numerous applications within the food processing industry, making it an indispensable asset for manufacturers striving for product excellence.

Typical Applications:

- ● Processed Meats: Producing the fine emulsion for frankfurters, bologna, and other cooked sausages. It is also critical for manufacturing pates, liverwurst, and luncheon meats, ensuring a smooth, consistent texture.

- ● Seafood Products: Essential for making fish balls, surimi, and various fish pastes that require fine chopping and binding.

- ● Plant-Based Alternatives: A core machine for processing ingredients like soy protein, vital wheat gluten, and vegetable purees to create meat-free sausages, burgers, and other textured products.

- ● Baby Food & Purees: Creating highly homogenized and smooth purees from fruits, vegetables, and meats, meeting strict consistency standards for infant nutrition.

- ● Confectionery & Dairy: Certain specialized applications for finely textured fillings, pastes, or blended dairy products.

Customer Feedback & Operational Benefits:

Feedback from a diverse range of clients consistently highlights the ZKZB-125's impact on product quality and operational efficiency. A medium-sized meat processor reported a 15% increase in product yield for emulsified sausages due to the vacuum technology, which significantly reduced air entrapment. This also led to a noticeable improvement in color stability and an extended shelf life of their finished goods. Another client in the plant-based protein sector lauded the machine's ability to create perfectly smooth and consistent textures for their vegan sausage products, a critical factor for consumer acceptance.

The machine's precise temperature monitoring system, often with an integrated cooling jacket, prevents the product from heating up excessively during the chopping process. This is vital for maintaining protein integrity and preventing fat separation, especially when processing temperature-sensitive ingredients. Operators appreciate the intuitive control panel, which simplifies recipe management and reduces training time. The robust design also translates into fewer breakdowns and lower maintenance costs, maximizing uptime.

Versatile applications across various food processing industries.

Technical Advantages and Enhanced Operational Efficiency

The distinctive technical advantages of a high-quality bowl cutter translate directly into superior product attributes and streamlined operational efficiency, making it an indispensable asset in modern food production.

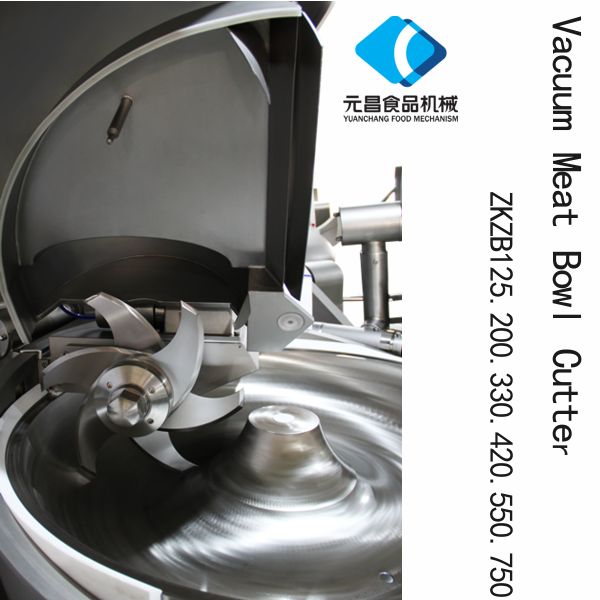

- ► Vacuum Technology: The ZKZB-125's deep vacuum capability (up to -0.09 MPa) is a game-changer. By removing air from the chopping area, it prevents oxidation, inhibits bacterial growth, and eliminates air bubbles. This results in products with brighter, more natural colors, significantly extended shelf life, and a denser, more consistent texture, crucial for premium goods like fine pates and high-quality sausages.

- ► Precision Temperature Control: Equipped with advanced temperature sensors and often a chilled water jacket, these machines can maintain optimal processing temperatures. This prevents protein denaturation and fat smearing, which can degrade product quality, especially for delicate emulsions. Precise control ensures consistent results batch after batch.

- ► Optimized Knife Design and Speed Control: The six-knife system, coupled with variable speeds up to 4800 RPM, allows for unparalleled control over the chopping process. This flexibility means operators can achieve anything from coarse grinds to extremely fine, stable emulsions. The high-speed knives generate intense shear, effectively breaking down cellular structures and liberating proteins for optimal binding.

- ► Robust Construction and Hygiene: Constructed from thick-gauge SUS304 stainless steel, the ZKZB-125 offers exceptional durability and easy cleaning. The polished surfaces and minimal crevices meet stringent hygiene standards, reducing the risk of contamination and facilitating quick changeovers between products.

- ► Energy Efficiency: Modern bowl cutters often incorporate energy-efficient motors and optimized mechanical designs. While total power is significant (e.g., 35.6 kW for ZKZB-125), the efficiency per unit of output is high, contributing to lower operating costs over the machine's lifespan. Advanced power management systems can dynamically adjust motor load, further enhancing efficiency.

- ► Advanced Automation and Safety: PLC control with intuitive HMI simplifies complex operations, allowing for programmable recipes and consistent processing. Integrated safety features, including interlocks and emergency stops, ensure operator protection and compliance with international safety regulations (e.g., CE standards).

These technical advancements collectively lead to significant improvements in product quality, reduction in waste, and optimization of production throughput, directly impacting profitability for food manufacturers.

Vendor Comparison: Selecting Your Ideal Bowl Chopper Machine

When investing in a bowl chopper machine, selecting the right vendor is as crucial as choosing the machine itself. The market offers a range of manufacturers, each with varying strengths. Discerning buyers focus not just on the bowl chopper machine price, but on a holistic value proposition encompassing technology, reliability, and support.

Key Considerations for Vendor Evaluation:

- ■ Technological Innovation: Does the vendor offer the latest advancements, such as high-vacuum capabilities, sophisticated temperature control, variable knife speeds, and intelligent PLC systems?

- ■ Material Quality & Construction: What grade of stainless steel is used? Are critical components like knife shafts and bearings sourced from reputable suppliers? Look for robust, heavy-duty construction.

- ■ Certifications & Compliance: Does the manufacturer hold ISO, CE, and other relevant food safety certifications (e.g., HACCP-compliant design)?

- ■ After-Sales Support: Availability of spare parts, technical assistance, warranty terms, and service engineers is paramount for long-term operational success.

- ■ Customization Capabilities: Can the vendor adapt the machine to specific production line requirements or unique product formulations?

- ■ Industry Reputation & Experience: A vendor with a long track record, positive customer testimonials, and a strong market presence generally indicates reliability.

Comparative Overview (Illustrative):

This comparison highlights that while many options exist, premium machines like the ZKZB-125 offer significant advantages in terms of control, hygiene, and product quality due to advanced standard features that might be optional or absent in general market offerings. Choosing a reputable manufacturer ensures not only superior machinery but also access to expert advice and reliable after-sales support, crucial for optimizing your return on investment.

Customized Solutions and Innovation

Recognizing that every food processing operation has unique requirements, leading manufacturers of the meat bowl cutter machine offer extensive customization options. This flexibility allows businesses to tailor equipment to their specific production capacities, product formulations, and existing line integration.

Tailoring to Specific Needs:

- ‣ Capacity Adjustments: While standard models like the ZKZB-125 (125 liters) cater to a wide range, manufacturers can offer larger or smaller bowl volumes.

- ‣ Knife Configurations: Options for different knife shapes or materials, depending on the specific product (e.g., highly viscous doughs, fibrous meats, delicate vegetables). Some applications may benefit from fewer or more knives.

- ‣ Integrated Loading/Unloading Systems: For seamless integration into an automated production line, customized conveyor belts, hoppers, and discharge mechanisms can be designed.

- ‣ Advanced Cooling Options: Beyond standard cooling jackets, specialized liquid nitrogen or CO2 injection systems can be integrated for ultra-precise temperature control, especially critical for raw-fermented sausage production or heat-sensitive ingredients.

- ‣ Enhanced PLC Programming: Custom software development allows for highly specific processing programs, integration with existing SCADA systems, and advanced data logging for quality control and traceability.

- ‣ Sanitation and Cleaning-in-Place (CIP) Integration: For operations requiring rapid and automated cleaning cycles, the bowl cutter can be adapted for CIP systems, reducing manual labor and ensuring superior hygiene.

The ability to offer bespoke solutions demonstrates a vendor's deep understanding of client needs and their commitment to long-term partnership. It ensures that the chosen bowl cutter is not just a piece of equipment but a fully optimized component of the production ecosystem, maximizing efficiency and product quality.

Tailored solutions meet specific production challenges.

Real-World Application Case Studies

The tangible benefits of a premium bowl cutter for sale are best illustrated through its successful deployment in diverse food processing environments. These case studies underscore the machine's role in improving product quality, increasing efficiency, and meeting stringent industry standards.

Case Study 1: Enhanced Sausage Production for a European Delicatessen

A prominent European delicatessen specializing in high-end cooked sausages faced challenges with inconsistent emulsification and short shelf life due to air entrapment in their previous machinery. Upon integrating a ZKZB-125 Vacuum Bowl Cutter, they observed a dramatic improvement. The deep vacuum capability (

Case Study 2: Achieving Perfect Consistency in Plant-Based Meat Analogues

A rapidly growing producer of plant-based meat alternatives struggled to achieve the desired fibrous, yet tender, texture for their vegan burger patties using traditional mixers. The challenge was to finely chop and bind diverse ingredients like pea protein, mushroom extracts, and vegetable oils without over-processing or losing textural integrity. The implementation of a ZKZB-125, with its variable knife speeds and precise temperature control, allowed them to achieve an ideal emulsification. The machine’s efficient processing ensured that the heat generated during chopping was minimized, preserving the delicate flavors and preventing unwanted structural changes in plant proteins. This led to a significant improvement in product mouthfeel and consumer appeal, positioning them as a leader in a competitive market segment.

Case Study 3: Optimizing Pet Food Emulsification for Premium Products

A manufacturer specializing in premium wet pet food needed a solution to create highly palatable and digestible food emulsions. Their existing equipment struggled with uniformity and consistency, leading to batch variations. By deploying a ZKZB-125, they were able to achieve exceptionally fine and stable emulsions of meat, vegetables, and grains. The robust motor and high-speed knife system efficiently processed tough ingredients, while the integrated cooling prevented product degradation. The result was a more consistent and nutritionally superior pet food, which in turn strengthened their brand's reputation for quality and commanded a higher market price. The ease of cleaning and maintenance also contributed to improved operational hygiene and reduced downtime.

These instances highlight the ZKZB-125's capacity to deliver measurable improvements in product quality, process efficiency, and overall business outcomes, solidifying its position as a trusted solution in advanced food processing.

Trustworthiness & Comprehensive Support

Investing in a significant piece of machinery like a bowl chopper machine requires confidence not only in the product but also in the long-term support provided by the vendor. Our commitment to trustworthiness is built upon transparency, robust support systems, and clear guarantees.

Frequently Asked Questions (FAQ):

Q: What is the typical lead time for a ZKZB-125 Vacuum Bowl Cutter?

A: Standard lead time for manufacturing and quality control is approximately 4-6 weeks from order confirmation. However, this can vary based on current production schedules and any requested customizations. We provide a precise lead time estimate upon quotation.

Q: What are the power requirements for this machine?

A: The ZKZB-125 has a total power requirement of 35.6 kW. It typically operates on a 3-phase, 380V/50Hz power supply, but voltage and frequency can be adapted to specific regional standards (e.g., 220V/60Hz, 480V/60Hz) upon request. Please consult our technical team for specific electrical configurations.

Q: How often do the knives need to be sharpened or replaced?

A: The lifespan of the knives depends heavily on the product being processed and operational intensity. Generally, with proper care, knives can last for several months to a year before requiring sharpening. We offer high-quality replacement knives and guidance on maintenance schedules. For optimal performance, regular inspection is recommended.

Q: Is training provided for operating the machine?

A: Yes, we offer comprehensive operator training, either on-site (depending on location and agreement) or virtually. Our training covers operation, maintenance, and basic troubleshooting to ensure your team can maximize the machine's efficiency and longevity. Detailed user manuals are also provided.

Lead Time and Fulfillment:

Our streamlined production process, coupled with robust supply chain management, ensures efficient order fulfillment. Typical lead times are as specified in the FAQ. We work closely with international logistics partners to ensure secure and timely delivery to your facility, managing all necessary customs documentation.

Warranty Commitments:

Each Vacuum Bowl Cutter ZKZB-125 comes with a standard 12-month warranty covering manufacturing defects and critical components. Extended warranty options are available. Our commitment ensures that your investment is protected, and any unforeseen issues are addressed promptly by our expert service team.

Comprehensive Customer Support:

Our dedicated after-sales support team is available to assist with installation guidance, technical queries, troubleshooting, and spare parts procurement. We maintain a full inventory of critical spare parts to minimize downtime. Our goal is to ensure continuous, optimal performance of your equipment throughout its extensive service life.

Dedicated support ensures optimal machine performance and longevity.

Conclusion: The Strategic Investment in Advanced Food Processing

The decision to acquire a high-quality bowl cutter, such as the ZKZB-125, is a strategic investment that fundamentally impacts a food manufacturer's capacity for innovation, product quality, and operational efficiency. From its meticulously engineered manufacturing process, employing food-grade stainless steel and advanced CNC machining, to its sophisticated vacuum technology and precision control systems, every aspect is designed to meet and exceed the rigorous demands of the modern food industry.

As global consumer preferences evolve towards healthier, more consistent, and diverse food products, the role of a reliable bowl cutter for sale becomes even more pronounced. It enables producers to achieve unparalleled control over texture, extend shelf life, and ensure hygienic processing, thereby securing a competitive edge. By carefully evaluating technical specifications, understanding application versatility, and prioritizing vendors with comprehensive support and customization capabilities, businesses can ensure they select a machine that not only meets current production needs but also supports future growth and product development. Investing in such advanced machinery is not merely a purchase; it is a commitment to excellence and a foundation for sustained success in the dynamic food processing landscape.

References

- Food Processing Equipment Market Size, Share & Trends Analysis Report, Grand View Research, Inc.

- International Standards for Food Machinery: Hygiene and Safety Requirements, ISO 14159:2008.

- Principles of Meat Science. 5th ed. by Forrest et al., Waveland Press, Inc.

- Handbook of Food Engineering. 2nd ed. by Heldman and Lund, CRC Press.

- Impact of Vacuum Technology on Meat Product Quality and Shelf Life, Journal of Food Science.

- Food and Drug Administration (FDA) Regulations for Food Contact Materials, 21 CFR.

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025