Buffalo Chopper Bowl: Industrial Meat & Vegetable Slicer

Navigating the Modern Food Processing Landscape: Trends and Innovations

The global food processing industry is undergoing a significant transformation, driven by evolving consumer demands for healthier, more convenient, and diverse food products. This shift necessitates advanced machinery capable of precise, hygienic, and efficient processing. At the heart of this evolution is the buffalo chopper bowl, a critical component within sophisticated meat processing equipment. Modern trends emphasize automation, digital integration, stringent hygiene standards, and the adoption of vacuum technology to enhance product quality and extend shelf life. This includes a growing demand for `commercial bowl chopper` and `industrial bowl chopper` solutions that offer higher throughput and consistent results. The integration of cutting-edge materials and precision engineering ensures that equipment, such as the `industrial meat bowl cutter`, meets the rigorous demands of large-scale production, delivering unparalleled performance. Furthermore, the increasing focus on food safety and regulatory compliance means that manufacturers are continuously innovating to provide machines that are not only efficient but also easy to clean and maintain, minimizing contamination risks. The advent of `vacuum bowl cutter` technology, specifically, represents a significant leap forward, allowing for improved texture, color, and reduced oxidation in processed products. These technological advancements are reshaping how meat, and indeed many other food types, are prepared for consumption, promising higher quality output and greater operational efficiency for businesses worldwide.

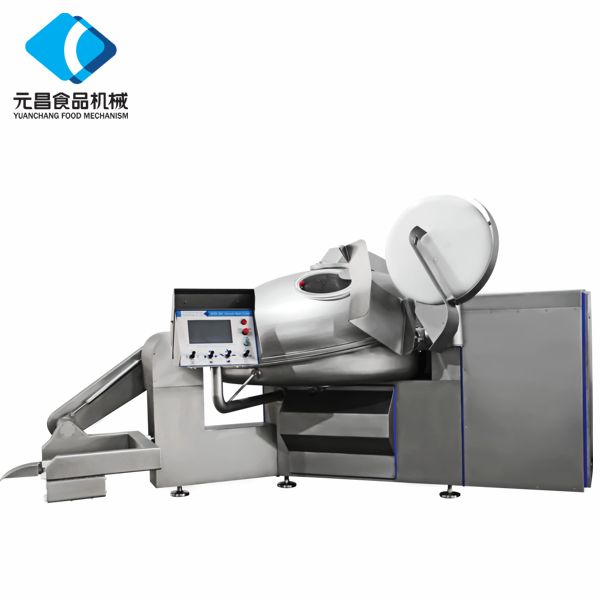

The Core Technology: Understanding Vacuum Meat Bowl Cutters (125L-750L Series)

Our Vacuum Meat Bowl Cutter, spanning capacities from 125L to 750L, embodies the pinnacle of meat processing technology. This sophisticated machine is engineered to finely chop, mix, and emulsify meat products under precise vacuum conditions, a feature that significantly differentiates it from conventional systems. The operational principle involves high-speed rotating blades working within a rotating bowl, ensuring uniform particle size and thorough mixing. Crucially, the vacuum environment prevents air incorporation, which is a common issue with traditional `bowl cutter` machines. This absence of oxygen mitigates oxidation, preserving the natural color, enhancing the binding properties, and extending the shelf life of the final product. Technical parameters of these units are meticulously designed for optimal performance; for instance, motor power ranges from 22 kW to 110 kW, providing ample force for even the toughest meat products. Blade speeds are adjustable, reaching up to 4500 RPM, allowing for versatile processing from coarse cuts to fine emulsions. Integrated temperature control systems, often utilizing nitrogen injection or chilling jackets, maintain optimal processing temperatures, preventing protein denaturation and ensuring product integrity. The robustness of the entire system, particularly the `double bowl chopper` variants, is crucial for continuous industrial operation, delivering consistent output quality and operational longevity. Advanced control interfaces allow operators to fine-tune every aspect of the process, from blade rotation and bowl speed to vacuum levels and processing time, ensuring repeatable and high-quality results across various product formulations.

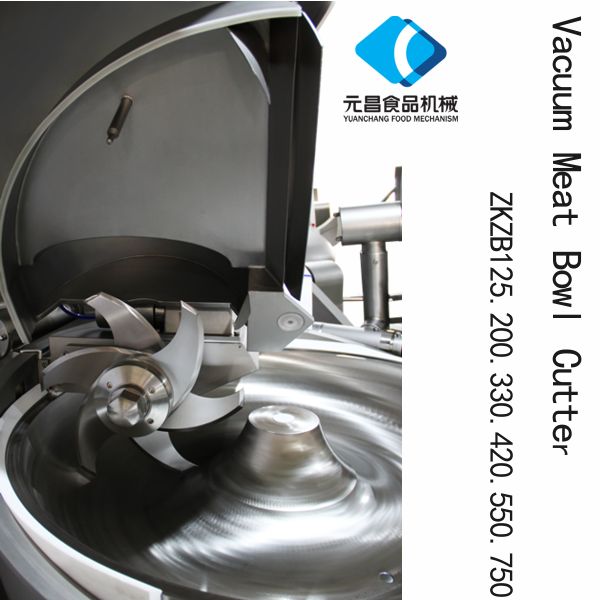

Manufacturing Excellence of the Buffalo Chopper Bowl and Key Components

The integrity and performance of a `bowl cutter` largely hinge on the superior manufacturing of its core components, especially the buffalo chopper bowl itself. For our Vacuum Meat Bowl Cutter, we prioritize materials like high-grade 304 or 316 stainless steel, chosen for their unparalleled corrosion resistance, hygienic properties, and durability, crucial for continuous contact with food products. The manufacturing process for the bowl involves precision casting or deep drawing, followed by meticulous CNC machining to achieve exact tolerances and a perfectly smooth, polished surface finish. This polished surface is not merely aesthetic; it is critical for preventing bacterial adhesion, facilitating thorough cleaning, and ensuring optimal product discharge, thereby meeting stringent food safety standards such as FDA and CE. Beyond the bowl, critical components like the blade assembly and drive shaft undergo sophisticated forging and heat treatment processes to enhance their strength and wear resistance. Every component, from the smallest bearing to the largest motor, is subject to rigorous quality control. This includes non-destructive testing, dimensional accuracy checks, and material composition verification against international standards like ISO 9001. The design life of these components, particularly the buffalo chopper bowl, is engineered for years of heavy-duty use in industrial settings, significantly reducing downtime and maintenance costs for our clients. In typical food processing scenarios, the precision manufacturing of these parts translates directly into tangible benefits, such as enhanced product yield due to uniform processing, reduced energy consumption from efficient mechanical operation, and superior hygiene compliance, which prevents cross-contamination. This commitment to manufacturing excellence ensures that our equipment not only performs optimally but also provides a long-term, reliable asset for any food processing operation.

Technical Advantages and Diverse Application Scenarios

The technical advantages offered by our advanced buffalo chopper bowl systems are multifaceted and profound, directly impacting product quality, shelf life, and operational efficiency. Foremost among these is the superior emulsification capability, which creates a highly stable, uniform product texture without compromising the protein structure. The vacuum processing environment is critical; by removing air from the processing chamber, it prevents undesirable oxidation, leading to products with brighter, more natural colors, improved flavor profiles, and significantly extended shelf life. This also reduces the formation of air pockets, resulting in denser, more consistent products, particularly vital for items like sausages and pates. Efficient mixing ensures that all ingredients, including spices and binders, are thoroughly incorporated, contributing to consistent taste and texture across batches. Compared to a simpler `vegetable slicer with bowl`, which is limited in its cutting capabilities and often lacks the hygienic design or power for meat processing, our systems offer unparalleled versatility and control. While a `valve bowl cutter` might refer to specialized applications, our focus remains on high-performance meat processing, providing a comprehensive solution.

The application scenarios for our Vacuum Meat Bowl Cutters are extensive and diverse, catering to a wide array of food processing needs. They are indispensable in the production of various processed meat products, including sausages, frankfurters, bologna, and mortadella, where a fine, stable emulsion is required. Beyond traditional meat items, these machines are also ideally suited for creating high-quality pates, liver pastes, and fine comminuted meat for baby food. The versatility extends to plant-based protein alternatives, where precision cutting and mixing are crucial for achieving desired textures and consistencies in vegan sausages, burgers, and other meat substitutes. Furthermore, the technology is highly effective in processing seafood products, such as fish balls and surimi, ensuring a smooth, elastic texture. Our machines have been successfully integrated into numerous client production lines globally, from small-to-medium enterprises seeking to scale up their operations to large industrial food manufacturers requiring high-volume, continuous processing. The ability to precisely control parameters like temperature and vacuum levels makes them adaptable to unique product formulations and specific processing requirements, demonstrating their inherent flexibility and value in modern food manufacturing.

Product Specifications & Manufacturer Comparison

Understanding the detailed specifications of a buffalo chopper bowl system is paramount for making an informed purchasing decision. Our Vacuum Meat Bowl Cutter series (125L-750L) is designed with precision and efficiency in mind. Below is a representative table outlining key parameters that define the performance and capabilities of these robust machines. These parameters, derived from extensive R&D and field testing, demonstrate the superiority of our engineering.

When comparing manufacturers of industrial food processing equipment, several factors beyond raw specifications come into play. Build quality, which includes the precision of fabrication and the robust design of the buffalo chopper bowl and its surrounding structure, directly impacts the machine's longevity and reliability. After-sales support, encompassing spare parts availability, technical assistance, and maintenance services, is crucial for minimizing downtime. Customization options are also a key differentiator, as specific production lines may require tailored solutions to integrate seamlessly. Furthermore, evaluating a manufacturer's compliance with international food safety standards (like HACCP, CE, and FDA) and their commitment to ongoing innovation provides insight into their dedication to quality and client success. Our product lineup demonstrates superior design and manufacturing, ensuring peak performance and adherence to the strictest hygiene protocols, positioning us as a leader in the `industrial meat bowl cutter` market.

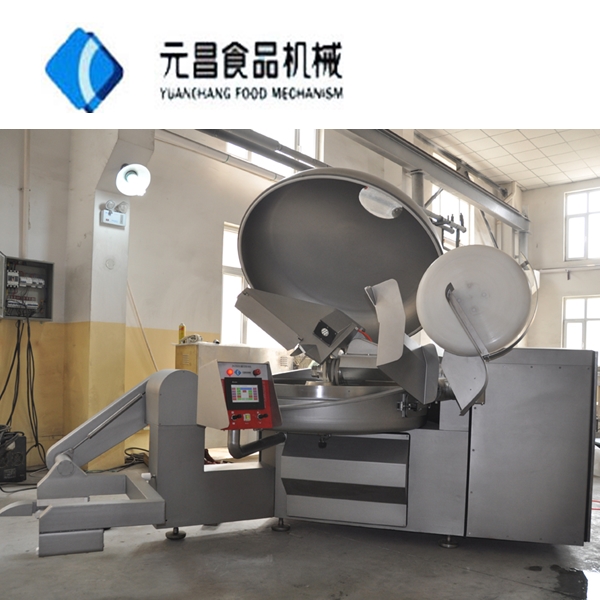

Customization, Application Cases, and Our Commitment to Excellence

Recognizing that every food processing operation has unique requirements, we offer extensive customization options for our Vacuum Meat Bowl Cutter series. This includes tailoring bowl capacities, integrating specific feeding and discharge systems, incorporating advanced PLC control systems for automation, and configuring specialized blade sets for particular product textures. For instance, a client producing high-volume, finely emulsified sausages might require a larger buffalo chopper bowl with higher blade speeds and continuous vacuum monitoring, while another focusing on coarse-ground products might need different blade configurations and lower speeds. Our engineering team collaborates closely with clients to develop bespoke solutions that seamlessly integrate into existing production lines, optimizing throughput and operational efficiency.

Our commitment to quality and customer satisfaction is evidenced by numerous successful application cases globally. A recent case involved a major European meat processor that implemented our 750L Vacuum Meat Bowl Cutter. They reported a 15% improvement in product yield and a noticeable enhancement in the texture and color uniformity of their premium sausage lines, primarily due to the consistent vacuum processing and precision of the buffalo chopper bowl system. Another example includes a burgeoning Asian plant-based food manufacturer, who leveraged our 125L model for developing new vegan patty formulations, praising its ability to achieve precise textures and efficient ingredient mixing.

We adhere strictly to international quality and safety standards, holding ISO 9001 certification for our manufacturing processes and ensuring all our machines comply with CE and FDA food contact material regulations. With over two decades of experience in the meat processing machinery industry, our expertise is built on a deep understanding of food technology and engineering. We provide comprehensive support, from initial consultation and bespoke design to installation, training, and long-term after-sales service. Our typical delivery cycle ranges from 8 to 12 weeks, depending on customization, and all our products come with a standard 12-month warranty, with extended support options available. Our dedicated customer support team is available 24/7 to address any technical queries or operational challenges, ensuring uninterrupted production for our valued clients.

Frequently Asked Questions (FAQ)

Q1: What are the primary benefits of a vacuum bowl cutter compared to a standard bowl cutter?

A vacuum `bowl cutter`, like our Vacuum Meat Bowl Cutter, offers several significant advantages over traditional non-vacuum models. The most notable benefit is the elimination of air from the product during processing. This prevents oxidation, which in turn preserves the natural color and flavor of the meat, extends the product's shelf life, and inhibits bacterial growth. It also leads to a denser, more consistent product texture, free from air pockets, which is crucial for high-quality emulsions and processed meats. Furthermore, the vacuum environment reduces product temperature rise during processing, minimizing protein denaturation and ensuring better binding properties. For any `industrial bowl chopper` application, the vacuum feature elevates the final product quality and efficiency substantially.

Q2: How important is the material of the buffalo chopper bowl and its maintenance for hygiene?

The material and surface finish of the buffalo chopper bowl are critically important for maintaining hygiene and preventing cross-contamination in food processing. Our bowls are crafted from high-grade 304 or 316 stainless steel, known for its superior corrosion resistance and non-porous surface. This material choice, combined with precision polishing, prevents food particles from adhering to the surface, making cleaning easier and more effective. Regular and thorough cleaning, following HACCP principles, is essential. We design our machines for easy access to all food contact surfaces for cleaning and inspection. Proper maintenance, including regular checks for wear and tear on blades and seals, ensures the continued hygienic operation and longevity of the `industrial meat bowl cutter`. Adhering to manufacturer guidelines for cleaning agents and procedures is also crucial to preserve the integrity of the material.

Q3: Can these machines process products other than meat?

While primarily designed as a `meat bowl cutter`, our Vacuum Meat Bowl Cutter series is highly versatile and capable of processing a wide range of food products beyond meat. This includes vegetable processing for purees and pastes, fish and seafood for surimi and fish balls, and plant-based protein alternatives for vegan sausages and patties. The adjustable blade speeds and vacuum control allow for precise processing of various consistencies and ingredients. While a dedicated `vegetable slicer with bowl` might be more suited for simple slicing, our buffalo chopper bowl systems excel in fine chopping, mixing, and emulsifying diverse food components, making them valuable assets in multi-product food manufacturing facilities. Clients have successfully utilized these machines for fine grinding cheeses, processing fruit pulps, and creating smooth confectionery fillings, showcasing their adaptability.

Authoritative References

- International Standards Organization (ISO). Quality management systems and food safety standards.

- Food and Drug Administration (FDA). Regulations for food contact materials and hygienic design in food processing equipment.

- European Hygienic Engineering & Design Group (EHEDG). Guidelines for hygienic design of food processing machinery.

- Meat and Livestock Australia (MLA). Technical reports on meat processing technologies and their impact on product quality.

- Journal of Food Science. Peer-reviewed articles on food processing advancements and ingredient interactions.

-

Meat Portioning Machine: Precision, Efficiency & Sustainability in Meat ProcessingNewsNov.24,2025

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025