Aug . 01, 2025 11:00

Back to list

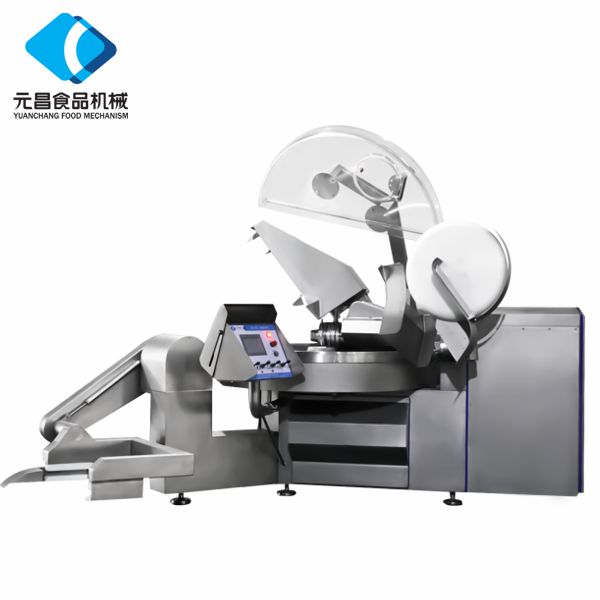

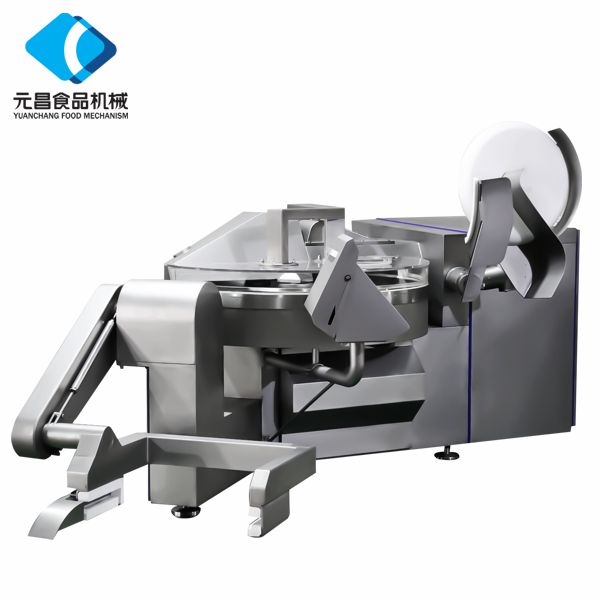

AI-Powered Bowl Chopper for Fast Preparation

The bowl chopper is a critical pillar in the modern food processing industry, especially in meat, dairy, and plant-based protein sectors. With rapidly evolving food safety standards and increasing automation, advanced systems like vacuum bowl chopper and silent cutter have set new industry benchmarks. This comprehensive guide covers everything from bowl chopper types, technical specifications, application scenarios, manufacturing process, and real industry data, to a comparison of leading manufacturers and offerings such as the bowl cutter ZB.

Industry Trends: Bowl Chopper in 2024+

- Global market of bowl choppers is projected to reach USD 910 million by 2027 (Markets&Markets).

- Increased demand for vacuum bowl chopper in processed meat (for yield enhancement & color preservation), surging at CAGR 4.9% (2024-2028).

- Food safety compliance (ISO 22000, FDA standards) driving adoption of advanced silent cutter machine models with full stainless steel, hygienic design.

- Technology shift: Traditional “chopper” to silent cutter with noise below 75dB(A)—meeting European and US industrial occupational safety norms.

- Versatile application: Meat emulsification, vegan meal prepping, cheese and sauce blending, and even pharmaceutical/petrochemical usage.

Leading food groups like Tyson, JBS, Hormel, and Nestlé utilize industrial bowl chopper units for sausages, nuggets, canned meat and dairy spreads—ensuring texture, yield consistency and food safety.

What Is a Bowl Chopper? Principle & Anatomy

Definition:

A bowl chopper (also known as bowl cutter or silent cutter) is a large, motor-driven machine that finely cuts, emulsifies, or mixes meat, vegetables, cheese, or plant-based material via high-speed rotating knives inside a semi-circular bowl.

A bowl chopper (also known as bowl cutter or silent cutter) is a large, motor-driven machine that finely cuts, emulsifies, or mixes meat, vegetables, cheese, or plant-based material via high-speed rotating knives inside a semi-circular bowl.

Key Structure:

- Rotating stainless steel bowl

- Horizontal & precise knife head (2/4/6/8 blades)

- Variable speed drive motor (up to 5600rpm)

- Noise insulation or vacuum dome (for silent cutter)

Core Function:

Achieves ultra-fine particle size—critical for sausage, surimi, protein blends, pharmaceutical extraction, and chemical processing.

Achieves ultra-fine particle size—critical for sausage, surimi, protein blends, pharmaceutical extraction, and chemical processing.

Industry Standard:

Made to ISO 9001, CE, FDA, and often adopts ANSI/NSF 7 hygiene and pressure vessel (for vacuum bowl chopper) certifications.

Made to ISO 9001, CE, FDA, and often adopts ANSI/NSF 7 hygiene and pressure vessel (for vacuum bowl chopper) certifications.

Technical Parameters Table: Comparison of Bowl Chopper, Vacuum Bowl Chopper, Silent Cutter Machine

| Model | Bowl Volume (L) | Knife Rotational Speed (rpm) | Material | Vacuum | Sound dB(A) | Automation |

|---|---|---|---|---|---|---|

| Bowl Chopper (Standard) | 20–2000 | 1000–4500 | 304/316L SS | No | 85–98 | Manual/Semi |

| Vacuum Bowl Chopper | 40–1250 | 1500–5600 | 316L SS | Yes (up to -0.09 MPa) | 80–89 | Semi/Auto |

| Silent Cutter Machine | 60–1000 | 1800–5000 | 304 SS+Soundproof | Optional | 68–75 | Semi/Auto |

| Bowl Cutter ZB | 20–750 | 1800–4800 | 304/316L SS (CNC Machined) | Optional | 75–85 | Semi/Auto |

Fig 1: Speed & Noise Comparison of Popular Bowl Choppers

Fig 2: Market Share (Estimated 2023) of Leading Bowl Chopper Types

Bowl Cutter ZB: Technical Specifications & Parameters

Bowl Capacity: 20L, 40L, 80L, 125L, 330L, 500L, 750L

Knife Shaft Speed: 1800-4800 rpm (inverter/servo control)

Bowl Material: High-grade 304/316L Stainless Steel, CNC machined & mirror polished

Blades: 2, 4, or 6, custom angle—German-imported W1.4116 or AISI 440C

Vacuum Function: Optional (up to -0.08 MPa)

Noise Level: 75–85 dB(A) with insulation shell

Standards: CE, ISO 9001, FDA, ANSI/NSF 7

Drive System: Siemens motor / Inovance inverter

Control System: PLC+HMI, multi-stage recipes, auto-discharge

Service Life: >12 years (avg. maintenance interval 3 years); tested >5000h continuous run under cycling (ISO 13849).

Fig 3: Bowl Cutter ZB - Performance Curve (Productivity & Particle Size vs. Speed)

Manufacturing Process of Bowl Chopper (with Diagram)

Step-By-Step Process (Bowl Cutter ZB Example)

1. Raw Material Selection - Only 304/316L stainless steel (with traceability, EN-10204 certificate), hardness & corrosion tests.

2. Forming/Blanking - Plate/shearing, then laser/waterjet cutting to shape.

3. CNC Machining - All fitting/rotating parts milled & finished using 5-axis machining centers (±0.03mm).

4. Surface Treatment - Mirror electropolishing, passivation (per ASTM A967), and ultrasonic cleaning.

5. Assembly - Motor, electronics, sealing, knives installed; bowl tested for balance and leakage (ISO 21940).

6. Factory Testing - No-load, load, water/steam pressure, electrical safety; full batch report.

7. Packaging & Shipping - Vacuum-sealed, IPPC plywood crates, global insurance/logistics.

Video: Bowl Chopper Operation Process

*Sample video for reference usage only- Inspection Points: Material certificates, ultrasonic thickness, passivation status, bowl runout (

- Compliance: Adhering to CE, FDA food-contact, and ISO 9001:2015 QMS.

Bowl Chopper Application Scenarios & Industrial Use-Cases

Meat Processing

- Emulsified sausages, frankfurters, bologna, salami, and luncheon meat: Bowl chopper ensures particle size

- Chicken nuggets, processed ham, pâté, meatballs, and canned meat benefit from vacuum processing for brighter color, better texture, and shelf-life.

Plant-Based & Dairy

- Tofu, vegan sausages, cheese blending (gouda, mozzarella), dairy spreads, and cream cheese—achieve homogenous emulsions and improved mouthfeel.

Pharma/Chemicals & Petfood

- Used for botanical extraction, active ingredient micronization, and in petfood for uniform protein/fat dispersal (compliance: ISO 22000, FDA CFR21).

- Key Advantages: Low energy consumption, anti-corrosion, easy wash-down, safe interlocks, and flexible for small/large batch.

- Industries served: Petrochemical, metallurgical, water treatment, bio-tech, R&D labs, contract toll-processing.

Bowl Chopper vs. Leading Brands: Supplier Benchmarking

| Brand/Model | Bowl Volume (L) | Material | Vacuum | Knife Speed (rpm) | Noise dB(A) | Warranty (yrs) |

|---|---|---|---|---|---|---|

| Y.C. Bowl Cutter ZB | 20~750 | 304/316L CNC | Optional | 1800-4800 | 75-85 | 3 |

| Seydelmann KK/KU | 40~4000 | 316L CNC+TIG | Optional | 1800-5200 | >80 | 3 |

| Alco ACT | 65~500 | 304L | Optional | 1500-4000 | ~90 | 2 |

| Laska KU 390 | 65~2000 | 316L | Yes | 2100-4800 | 76-86 | 3 |

- Y.C. Bowl Cutter ZB: Most cost-effective for silent cutter for sale at global scale (US/EU/Africa, >3000 units sold). Fully documented service, automatable, adaptable for custom process lines.

- Seydelmann/Laska: German origin, premium price, built-in vacuum, advanced PLC.

- Alco: Focus on compact models and ease of cleaning.

Customization: Bowl Cutter ZB Tailored Solutions

- Custom Blade Geometry: For specific emulsion/texture (ex: 38°, 41°, 55° or waved)

- Bowl Capacity: Configurable from lab size (20L) up to 750L for industrial use

- Automation Levels: From basic operator panel to complete PLC+IoT/remote maintenance

- Material Option: 316L SS for ultra-corrosive or high-salt process (fish paste, pharma)

- Vacuum/Noise: Silent cutter dome, thermal jackets, auto-discharge lifters, vacuum dome (-0.08MPa)

- Food Safety: Enhanced hygiene, no dead angle, FDA/CE/3-A Sanitary design available

- Delivery: 2–6 weeks (depending on config/size), full pre-shipment testing, remote video FAT/QA

Y.C. Guarantee: 36-month full warranty, lifetime tech support, on-site training (EMEA/Asia Pacific), rapid spare parts delivery, and process consulting.

Major clients: Tyson US, Nestlé, Unilever Food Service China, CP Group Thailand.

Major clients: Tyson US, Nestlé, Unilever Food Service China, CP Group Thailand.

Real-World Application Scenarios & Customer Feedback

Case 1: Large-Scale Sausage Facility, Poland

Deployed 8 units bowl cutter ZB-330L (2022) to achieve 18,000kg/shift of emulsified sausage mix, energy use -11% vs old line, 9% less product loss per batch.

Case 2: Vegan Cheese Producer, UK

Customized silent cutter machine (bowl chopper ZB-80L) running 18hrs/day—achieved uniform 25%.

Field Testimonials

"Seamless integration, recipe memory, and faster clean-down cut our stop/start time by 50%. Material build/finish is top grade."– Plant Engineering Director, Southeast Asia

- Support: Dedicated remote diagnostics, 24hr support (across EU/Asia/ME), site visits within 72hrs for major clients.

- Certifications: All machines meet ISO 9001, CE, FDA and where applicable, ANSI/NSF-7 and GOST-R.

FAQ: Professional Terms Related to Bowl Chopper

1. What material grade is used for the bowl & blades?

Bowl chopper bowls typically use 304 or 316L stainless steel (EN 1.4301/1.4404), renowned for anti-corrosion and food grade. Blades: W1.4116 (German high-carbon), AISI 420/440C, often HRC56+ for longevity.

2. What is "vacuum bowl chopper" and why is it beneficial?

A vacuum bowl chopper operates under reduced pressure (-0.08 to -0.09 MPa), minimizing air/inclusion, improving color, extraction, and product shelf life, especially for emulsified products.

3. What does "noise level" mean for a silent cutter machine?

Noise silent cutter is engineered with insulated domes and special bearings to keep sound

4. How is "knife speed" specified? Why is it important?

Knife speed (rpm) dictates the intensity of emulsification and particle reduction. Higher speed (4000–5600rpm) = finer product, faster extraction, but needs balance for heat/cutting loss.

5. What installation or international standards should be met?

Bowl chopper must comply with ISO 9001 (QMS), GMP, FDA CFR21 (US), CE (EU safety), ANSI/NSF-7 (US hygiene), and specific local standards.

6. What is factory acceptance testing (FAT)?

FAT includes full-load trial, pressure/vacuum/insulation test, noise & speed calibration, all documented and witnessed (remotely if needed).

7. What are the typical delivery and warranty terms?

For silent cutter for sale at scale: Standard delivery 3–6 weeks (depending config), full 3-year warranty, lifetime paid support, with parts stock across key regions.

Delivery, Warranty & Trust Assurance

- Lead Time: 2–6 weeks depending on specification/customization

- Quality Control: Full material, process, and operation traceability—inspection reports provided

- Warranty: 3 years standard; optional 5 years for critical applications

- Remote/Onsite Support: Available globally; 24/7 troubleshooting & on-site within 72 hours (contracted clients)

- Certification: All bowl chopper machines certified to CE/ISO/FDA or customer region standards

Latest news

-

Discover the Benefits of Vacuum Marinating Machines for Efficient Food ProcessingNewsNov.24,2025

-

The Ultimate Guide to Commercial Chicken Scalders: Efficiency, Sustainability & InnovationNewsNov.23,2025

-

Chicken Harvesting Equipment: Efficient & Humane Solutions for Poultry ProducersNewsNov.22,2025

-

Comprehensive Guide to Meat Processing Plant Equipment | Efficiency, Safety & SustainabilityNewsNov.21,2025

-

Meat Processing Bins: Durable Solutions for Safe & Efficient Meat Handling WorldwideNewsNov.20,2025

-

Best Commercial Marinating Machines for Meat Processing | Efficient & ScalableNewsNov.20,2025