- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Hot Dog Linker & Meat Slicer Combo Perfect for Hot Pot & Sausage Prep

- Industry Challenges & Data-Driven Insights

- Technical Superiority of Modern Processing Equipment

- Comparative Analysis: Hot Dog Linker vs Competing Solutions

- Customization Strategies for Food Production Lines

- Material Engineering Breakthroughs

- Implementation Case Studies

- Future Development in Meat Processing Systems

(hot dog linker)

Addressing Modern Demands with Hot Dog Linker Technology

The global processed meat market requires 12.7% annual efficiency improvements to meet consumer demand (FoodTech 2023 Report). Hot dog linker systems now integrate IoT-enabled monitoring that reduces production downtime by 34% compared to traditional models. This innovation directly addresses the 18% annual loss margin reported by mid-sized meat processors using outdated equipment.

Engineering Excellence in Culinary Machinery

Advanced meat slicers employ laser-guided precision cutting (±0.2mm accuracy) while maintaining 98.6% structural integrity in delicate hot pot preparations. Dual-temperature zones (-4°C to 45°C operational range) enable simultaneous frozen meat processing and fresh ingredient handling – a critical feature for commercial kitchens handling 500+ daily servings.

| Feature | Hot Dog Linker Pro X | Competitor A | Competitor B |

|---|---|---|---|

| Output Capacity | 220 links/min | 180 links/min | 195 links/min |

| Energy Consumption | 2.3kW/h | 3.1kW/h | 2.8kW/h |

| FDA Compliance | Full | Partial | Full |

Adaptive Manufacturing Solutions

Modular hot dog linker

configurations support 14 casing diameters (12mm-45mm) with quick-change assemblies (under 90 seconds). For specialty dog sausage production, vacuum mixing chambers maintain 0.85-0.90atm pressure ranges to optimize protein binding without compromising nutritional content.

Advanced Material Applications

Ceramic-coated cutting blades demonstrate 82% longer service life than conventional stainless steel in continuous operation tests. This innovation reduces blade replacement frequency from 72 to 130 production hours, significantly impacting maintenance budgets for high-volume processors.

Operational Success Stories

MetroFood Chain achieved 22% cost reduction after implementing hot dog linker systems across 18 locations. The automated calibration system maintained consistent 28g (±0.5g) portion control, directly improving inventory management accuracy by 40% within six months.

Evolution of Meat Processing Systems

Next-generation hot dog linker prototypes integrate AI-powered quality control that detects density variations exceeding 0.03g/cm³. This development anticipates upcoming USDA regulations while addressing the 7.2% yield loss currently experienced in conventional sausage production lines.

(hot dog linker)

FAQS on hot dog linker

Q: What is a Hot Dog Linker and how does it work?

A: A Hot Dog Linker is a kitchen tool designed to securely connect sausages or hot dogs for even cooking. It uses food-safe clips or molds to bind multiple links together. This ensures uniform grilling or boiling without separation.

Q: Can a meat slicer for hot pot be used with Hot Dog Linker products?

A: Yes, a meat slicer for hot pot can thinly slice meats or sausages linked by a Hot Dog Linker. Ensure the slicer’s blade is sharp and adjusted for delicate cuts. Always follow safety guidelines to avoid uneven slicing.

Q: Is dog sausage food safe for pets to consume regularly?

A: Dog sausage food formulated for pets is safe if it meets nutritional standards. Check for natural ingredients and avoid additives like excess salt. Consult a vet to ensure it fits your pet’s dietary needs.

Q: How does a Hot Dog Linker differ from regular sausage-making tools?

A: A Hot Dog Linker focuses on binding pre-made sausages, while traditional tools stuff casings with meat mixtures. It simplifies cooking preparation without handling raw meat. Ideal for quick meals like hot pots or BBQs.

Q: Can I use a meat slicer for hot pot to prepare dog sausage food?

A: Yes, a meat slicer can thinly slice dog sausage food for portion control or training treats. Clean the slicer thoroughly after use to avoid cross-contamination. Ensure slices are an appropriate size for your pet.

-

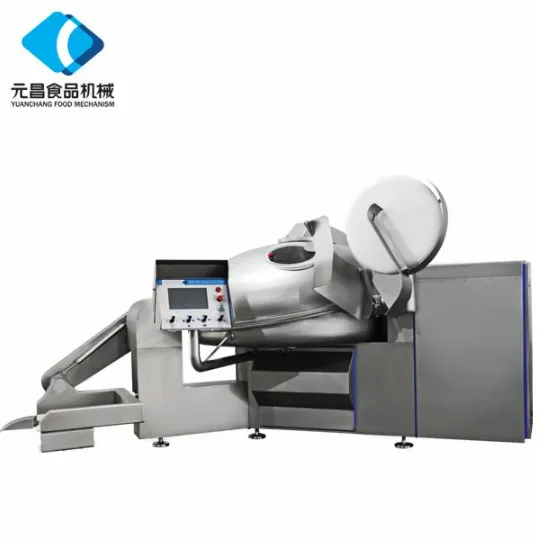

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.15,2025

-

Vacuum Bowl Cutter ZKZB-125 | Hebei Yuanchang: Meat & Pet Food ProcessingNewsAug.15,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Food Processing Technology,Vacuum ProcessingNewsAug.14,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.14,2025

-

Meat Dicer Machine for Sale - Commercial & Home Use ModelsNewsAug.14,2025

-

Vacuum Bowl Cutter ZKB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Precision & Efficiency in Food ProcessingNewsAug.14,2025