- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Electric Meat Slicer Machine for Home & Commercial Use – Precise Cutting, Easy Cleaning, Powerful Motor

- Introduction to Electric Meat Slicer Machines: Revolutionizing Food Preparation

- How Electric Meat Slicer Machines Work: Engineering and Efficiency

- Technical Advantages: Precision, Speed, and Consistency

- Comparative Analysis of Market-Leading Brands

- Custom Solutions: Tailoring Electric Slicers for Distinct Needs

- Practical Applications: Real-World Case Studies

- Why Choose an Electric Meat Slicer Machine for Your Business?

(electric meat slicer machine)

Introduction to Electric Meat Slicer Machine: Revolutionizing Food Preparation

The electric meat slicer machine

has become an essential tool for food service establishments, catering businesses, and home kitchens that demand efficiency and precision. With the surge in processed meat consumption—estimated at over 350 million metric tons globally in 2023—kitchen operations require equipment that can keep pace with demand. As the food industry evolves, the demand for specialized slicers, including frozen meat slicer electric models, continues to rise, offering both safety and consistency.

Modern food preparation is not just about speed; it demands uniformity, hygiene, and minimized waste. Electric frozen meat slicers, designed for seamless slicing of chilled or fully frozen products, adhere to strict industry standards, resulting in streamlined workflows and improved product yield. This segment dissects how the electric meat slicer machine is transforming kitchens worldwide.

How Electric Meat Slicer Machines Work: Engineering and Efficiency

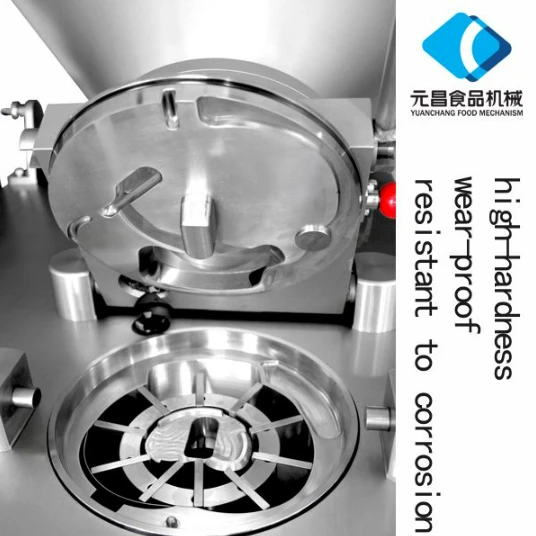

At the heart of every electric meat slicer machine lies a robust motor, precision-crafted blades, and a user-friendly interface. The process begins with the operator positioning the meat—sometimes fully frozen for hygiene and rigidity—against an adjustable carriage. When powered, the slicing blade operates at speeds between 250 and 400 RPM, enabling swift, uniform cuts.

Cutting through both soft and dense meats is made possible by specialized blade materials such as hardened stainless steel, sometimes coated with Teflon to minimize sticking. The drive system, often belt-driven or gear-driven, impacts both power transmission and operational noise. Advanced slicers incorporate features such as variable thickness control (from paper-thin 0.2mm up to 25mm), safety interlocks, and removable components for sanitation.

Unlike manual counterparts, electric frozen meat slicers streamline the handling of products at sub-zero temperatures, reducing operator fatigue and controlling slice thickness with precision. The integrated systems reduce time spent per operation by up to 70% compared to traditional methods.

Technical Advantages: Precision, Speed, and Consistency

Investing in electric meat slicer machines yields tangible operational advantages. Industry data demonstrates that businesses utilizing electric slicers can increase daily output by over 120% without sacrificing consistency. Key benefits include:

- Precision: Consistent slice thickness ensures visual appeal and uniform cooking in commercial kitchens.

- Speed: Capable of slicing up to 600 pounds of meat per hour, a dramatic increase over manual slicing.

- Waste Reduction: Accuracy in portioning minimizes offcuts, boosting yield by up to 18%.

- Safety: Reduced operator contact with the blade, aided by safety guards and non-slip bases, translates into fewer workplace injuries.

Additionally, the automation available in frozen meat slicer electric equipment addresses specific challenges in the processing of frozen meats, maintaining the product integrity by reducing cellular breakdown and ensuring food safety compliance.

Comparative Analysis of Market-Leading Brands

Selecting the right electric meat slicer machine hinges on comparing technical features, cost, durability, and after-sales support. The table below contrasts leading brands across critical parameters, empowering buyers to make informed decisions:

| Brand | Motor Power (W) | Slice Thickness Range (mm) | Production Rate (kg/hr) | Blade Diameter (mm) | Noise Level (dB) | Warranty (years) | Special Features |

|---|---|---|---|---|---|---|---|

| ProCut 450E | 450 | 0.5 – 25 | 120 | 300 | 68 | 2 | Automatic Carriage, Safety Interlock |

| SliceMaster QX | 500 | 0.2 – 22 | 150 | 330 | 66 | 3 | Self-Sharpening, Digital Control |

| Frozen Edge 300F | 400 | 1 – 20 | 100 | 300 | 70 | 1 | Designed for Frozen Meats, Removable Blade System |

| ChefSlice Pro FX | 480 | 0.5 – 25 | 130 | 320 | 67 | 2 | LED Display, Quick Release Tray |

From automated adjustments and advanced blade sharpening systems to low-maintenance construction, these differences highlight why thorough brand assessment remains vital. Premium brands often justify a higher price with enhanced durability, noise reduction, and unique features tailored for frozen applications.

Custom Solutions: Tailoring Electric Slicers for Distinct Needs

Off-the-shelf electric meat slicer machines address most applications, but certain operations demand tailored solutions. High-volume meat processors, specialty delis, and industrial kitchens often require customizations based on workflow, physical space, or particular product specifications.

- Blade Customization: Selectable diameter and material accommodate various foods—be it ultra-thin beef carpaccio or thick chops.

- Conveyor Integration: Ensures seamless transfer to further processing lines, suited for large-scale frozen meat facilities.

- Programmable Slicing Cycles: Optimize batch consistency and minimize operator intervention for repetitive tasks.

- Automation Upgrades: Optional robotic arms reduce manual feeding, improving throughput and ergonomics.

- Advanced Safety Configurations: Laser sensors, emergency stops, and tamper-proof locking mechanisms for compliance with local regulations.

Many manufacturers collaborate closely with clients to design units that meet international safety standards (such as CE or NSF), preserve cutting-edge performance, and align with future production expansion plans. The result—maximum return on investment and minimized downtime.

Practical Applications: Real-World Case Studies

Deploying electric and frozen meat slicer electric machines has redefined operational benchmarks across commercial kitchens, meat processing plants, and food retailers. Several illustrative examples underscore their transformative impact:

- Chain Supermarket Delicatessen: After transitioning to mid-sized electric slicers, daily throughput increased from 700 to 1,600 pounds, while labor costs dropped by 40%. The risk of repetitive strain injuries among staff fell dramatically.

- Artisan Charcuterie Producer: Integrating a programmable, high-precision frozen meat slicer electric into the production line ensured uniformity in wafer-thin prosciutto slices. Result: 99.4% product consistency and a 12% uptick in retail sales due to superior presentation.

- Industrial Meat Facility: Custom-engineered, conveyor-integrated slicers enabled the processing of 4 metric tons daily, up from 1.5 metric tons. Automated sanitation features reduced cleaning time by 70%, improving hygiene compliance scores.

- Fast-Casual Restaurant Group: Adopting compact, easy-clean slicers allowed franchise locations to maintain food quality across 80 outlets, receiving positive feedback from both staff and customers.

Across these sectors, data-driven investments in electric slicing technology are yielding productivity improvements, reduced product loss, and safer environments for staff.

Why Choose an Electric Meat Slicer Machine for Your Business?

For food businesses aiming to remain competitive, the advantages of integrating an electric meat slicer machine go beyond speed or ease-of-use. The amalgamation of advanced safety systems, ergonomic operation, and precise portion control offers critical value in today’s high-demand environment.

By streamlining slicing tasks, minimizing wastage, and enabling versatility—from delicately shaved frozen cuts to robust steak slices—these machines empower teams to focus on quality and customer satisfaction. With industry statistics showing that up to 22% of operational costs can be attributed to inefficiencies, transitioning to modern electric or frozen meat slicer electric units is a forward-thinking, economically responsible decision.

Business owners and operators who prioritize investment in reliable and intelligently engineered equipment position their brands at the forefront of food service excellence, ensuring lasting benefits for both workforce and clientele.

(electric meat slicer machine)

FAQS on electric meat slicer machine

Q: What is an electric meat slicer machine?

A: An electric meat slicer machine is a kitchen device that uses a powered blade to slice meat quickly and evenly. It can be used for both home and commercial purposes. This machine saves time and ensures uniform meat slices.Q: Can an electric frozen meat slicer cut frozen meat?

A: Yes, an electric frozen meat slicer is specially designed to handle and slice frozen meat efficiently. Its powerful motor and sharp blade make slicing frozen foods easy. Always follow the manufacturer's safety instructions.Q: How do I clean an electric meat slicer machine?

A: Unplug the machine and disassemble the removable parts according to the manual. Wipe all components with warm, soapy water, and dry them thoroughly before reassembling. Regular cleaning helps maintain hygiene and extend machine life.Q: What advantages does a frozen meat slicer electric offer over manual slicing?

A: An electric frozen meat slicer saves time and effort compared to manual slicing. It ensures consistent thickness and cleaner cuts, even for frozen meat. This results in more professional-looking and evenly cooked dishes.Q: Is an electric meat slicer machine safe to use at home?

A: Electric meat slicer machines are safe if proper operating guidelines and safety precautions are followed. Most models feature safety guards and non-slip bases for added protection. Always supervise use, especially around children.-

Dry Aging Machine for Meat – Premium Meat Aging Machine for Home & Commercial UseNewsJul.07,2025

-

Commercial Bowl Cutter for Efficient Meat Processing Bowl Meat Cutter at Best PriceNewsJul.06,2025

-

Sausage Filling Machines – Automatic Sausage Filler & Efficient Linking Equipment for Meat ProcessingNewsJul.06,2025

-

High-Quality Meat Grinders – Tabletop & Electric Options for Home & BusinessNewsJul.05,2025

-

Drying Chamber for Sausage Products - Efficient & Consistent Maturation SolutionsNewsJul.05,2025