- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

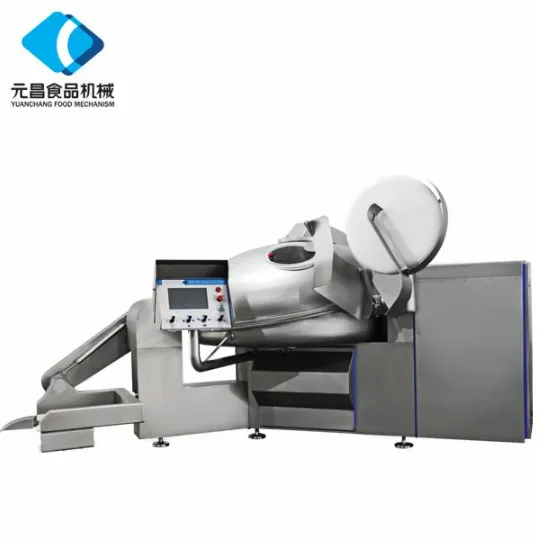

Meat Bowl Cutter Machine High-Speed Industrial Meat Processor

- Introduction to Meat Bowl Cutter Machines

- Key Technological Advancements

- Performance Metrics Across Leading Brands

- Customization for Diverse Industrial Needs

- Real-World Applications in Meat Processing

- Maintenance and Longevity Best Practices

- Future Trends in Industrial Meat Bowl Cutters

(meat bowl cutter machine)

Understanding the Role of Meat Bowl Cutter Machines in Modern Processing

A meat bowl cutter machine

is the backbone of high-volume meat processing, designed to emulsify, mix, and homogenize raw materials with precision. These industrial-grade systems handle batches ranging from 50 kg to 500 kg per cycle, reducing labor costs by up to 40% compared to manual methods. Industries relying on sausage production, pâté, or ready-to-cook meals leverage bowl cutter machines to achieve consistent texture and fat distribution—critical for product quality compliance with ISO 22000 and HACCP standards.

Key Technological Advancements

Modern bowl cutter machines integrate variable-frequency drives (VFDs) to adjust blade speeds between 1,500–3,000 RPM, optimizing energy consumption by 18–22%. Advanced models feature dual cooling systems (refrigeration + vacuum) to maintain temperatures below 12°C, preventing protein denaturation. Stainless steel blades with nano-coated surfaces enhance durability, while IoT-enabled sensors monitor torque and temperature in real time, reducing downtime by 30%.

Performance Metrics Across Leading Brands

| Brand | Power (kW) | Capacity (kg/cycle) | Noise Level (dB) | Price Range (USD) |

|---|---|---|---|---|

| Kilia ProfiCut | 15 | 200 | 72 | 32,000–38,000 |

| Sirman TCG-300 | 18 | 300 | 68 | 45,000–52,000 |

| Weber MT-800 | 22 | 500 | 65 | 68,000–75,000 |

Customization for Diverse Industrial Needs

Manufacturers now offer modular designs for industrial meat bowl cutters, allowing operators to retrofit attachments like vacuum fillers or spice injectors. For halal/kosher-certified facilities, dedicated stainless steel contact surfaces and segregated lubrication systems are available. Low-capacity variants (50–100 kg cycles) cater to artisanal producers, while mega-bowl configurations support airline catering or military ration production.

Real-World Applications in Meat Processing

A poultry processor in Germany reported a 27% yield increase after switching to a vacuum-assisted bowl cutter machine, minimizing air pockets in chicken sausages. Similarly, a U.S.-based plant reduced ingredient waste by 19% using AI-driven batch optimization software paired with their cutter system. These cases highlight how precise emulsification directly impacts profitability.

Maintenance and Longevity Best Practices

Daily sanitation with food-grade alkaline detergents extends component life by 15–20%. Replacing carbon steel blades every 1,200 operating hours (or 6 months) prevents micro-fractures. Technicians recommend quarterly calibration of torque sensors and annual motor rewinding for machines exceeding 5,000 hours annually.

Future Trends in Industrial Meat Bowl Cutters

The next generation of meat bowl cutter machines will prioritize sustainability, with prototypes achieving 25% energy reduction via regenerative braking systems. Hybrid models combining bowl cutters and sous-vide cookers are under development, targeting ready-meal manufacturers. As global demand for processed meat grows at 4.2% CAGR, innovations in bowl cutter technology will remain pivotal to scaling production without compromising quality.

(meat bowl cutter machine)

FAQS on meat bowl cutter machine

Q: What is a meat bowl cutter machine used for?

A: A meat bowl cutter machine is designed to finely chop, mix, and emulsify meat and other ingredients for products like sausages, patties, and deli meats. It ensures consistent texture and efficient blending in industrial food processing.

Q: What are the advantages of using a bowl cutter machine in meat processing?

A: Bowl cutter machines improve productivity by rapidly processing large meat batches, enhancing flavor distribution, and achieving uniform texture. They also reduce manual labor and ensure food safety compliance.

Q: How do I clean an industrial meat bowl cutter machine?

A: Clean the machine by disassembling removable parts, using food-safe detergents, and sanitizing surfaces. Always follow the manufacturer’s guidelines to avoid damage and maintain hygiene standards.

Q: What capacity options are available for industrial meat bowl cutters?

A: Industrial models range from 20-liter to over 200-liter bowl capacities, catering to small-scale operations or large production lines. Choose based on your daily output requirements and space constraints.

Q: Can a bowl cutter machine handle different types of meat?

A: Yes, bowl cutters process poultry, beef, pork, and fish, adjusting blade speed and mixing time for desired results. Some models include pre-set programs for specific meat textures.

-

Vacuum Bowl Cutter ZKZB-125 | Hebei Yuanchang: Meat & Pet Food ProcessingNewsAug.15,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Food Processing Technology,Vacuum ProcessingNewsAug.14,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.14,2025

-

Meat Dicer Machine for Sale - Commercial & Home Use ModelsNewsAug.14,2025

-

Vacuum Bowl Cutter ZKB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Precision & Efficiency in Food ProcessingNewsAug.14,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.13,2025