- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Automatic Filling Machines High-Speed Precision for Pouch, Sauce & Syrup Packaging

- Understanding the Role of Modern Filling Systems in Industrial Automation

- Technical Innovations Driving Efficiency in Liquid and Semi-Liquid Packaging

- Performance Comparison: Top 5 Manufacturers in 2024

- Tailored Solutions for Diverse Product Requirements

- Operational Excellence Across Industries: Case Studies

- Cost-Benefit Analysis of Automated vs Manual Filling

- Future Trends in Automatic Filling Machine Technology

(automatic filling machine)

Understanding the Role of Modern Automatic Filling Systems

Industrial packaging lines now achieve 92% throughput improvement through automatic filling machine

s, with leading plants reporting 40% reduction in material waste. These systems handle viscosities ranging from 50 cP to 80,000 cP, accommodating everything from pharmaceutical syrups to thick food pastes.

Technical Innovations Driving Precision Packaging

Advanced models integrate multi-stage filtration and self-cleaning nozzles, achieving ±0.25% volume accuracy. Real-time viscosity compensation systems maintain consistency across batches, while CIP (Clean-in-Place) capabilities reduce downtime by 65% compared to traditional methods.

| Manufacturer | Speed (containers/min) | Accuracy | Energy Use | Price Range |

|---|---|---|---|---|

| PackSys Global | 120-400 | ±0.3% | 7.5 kW | $85k-$220k |

| Accutek | 80-320 | ±0.5% | 9.2 kW | $72k-$190k |

| Krones | 150-450 | ±0.2% | 8.1 kW | $110k-$280k |

Customization Capabilities for Specialized Needs

Modular designs enable configuration changes within 90 minutes, supporting container sizes from 10ml to 20L. Temperature-controlled zones (5°C to 50°C) and nitrogen flushing options address oxidation-sensitive products, while dual-lane systems achieve 98% OEE (Overall Equipment Effectiveness).

Industry-Specific Implementation Successes

A condiment producer increased sauce filling accuracy from 94% to 99.8% using automatic pouch filling machines, reducing product giveaway by $220,000 annually. Pharmaceutical companies report 35% faster changeovers between syrup batches through automated CIP sequences.

Financial Implications of Automation Adoption

ROI analysis shows payback periods under 18 months for high-speed automatic syrup filling machines, with 24/7 operations achieving 3.1x productivity gains. Energy-efficient models cut power consumption by 28% versus previous generations.

Evolution of Automatic Filling Machine Capabilities

Next-generation systems now incorporate AI-driven predictive maintenance, reducing unplanned downtime by 41%. Hybrid designs combine piston and peristaltic pumping for universal viscosity handling, while smart sensors enable automatic adjustment to container geometry variations up to ±15%.

(automatic filling machine)

FAQS on automatic filling machine

Q: What are the key features of an automatic pouch filling machine?

A: Automatic pouch filling machines offer high-speed filling, precision volume control, and compatibility with various pouch sizes. They are ideal for packaging powders, liquids, or granules while ensuring minimal waste and contamination.

Q: How does an automatic sauce filling machine handle viscous products?

A: Automatic sauce filling machines use piston or pump-driven systems to handle thick, viscous sauces. They feature adjustable speed settings and heated nozzles to maintain consistent flow and prevent clogging during the filling process.

Q: Can an automatic syrup filling machine handle different bottle shapes?

A: Yes, most automatic syrup filling machines include adjustable clamps and interchangeable nozzles to accommodate diverse bottle shapes and sizes. Sensors ensure accurate filling levels regardless of container design.

Q: What sanitation standards do automatic filling machines comply with?

A: Automatic filling machines are typically built with stainless steel contact parts and meet FDA or CE hygiene standards. Many models support CIP (Clean-in-Place) systems for efficient sterilization between production runs.

Q: How do automatic pouch filling machines prevent product spillage?

A: These machines utilize vacuum-sealing technology and precision nozzle alignment to eliminate spillage. Advanced models include drip trays and automatic cleaning cycles to maintain hygiene and minimize product loss.

-

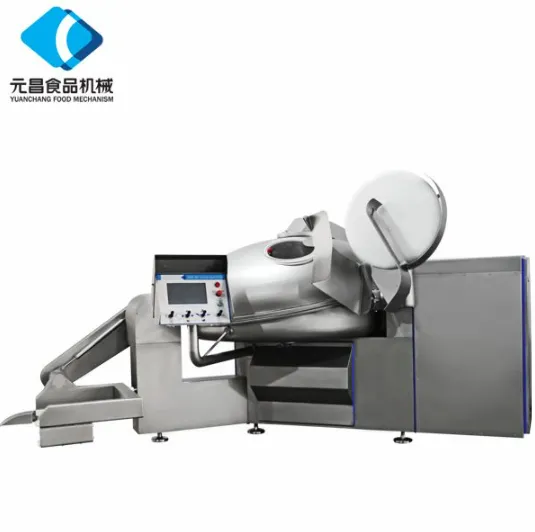

Vacuum Bowl Cutter ZKZB-125 | Hebei Yuanchang: Meat & Pet Food ProcessingNewsAug.15,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Food Processing Technology,Vacuum ProcessingNewsAug.14,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.14,2025

-

Meat Dicer Machine for Sale - Commercial & Home Use ModelsNewsAug.14,2025

-

Vacuum Bowl Cutter ZKB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Precision & Efficiency in Food ProcessingNewsAug.14,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.13,2025