- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

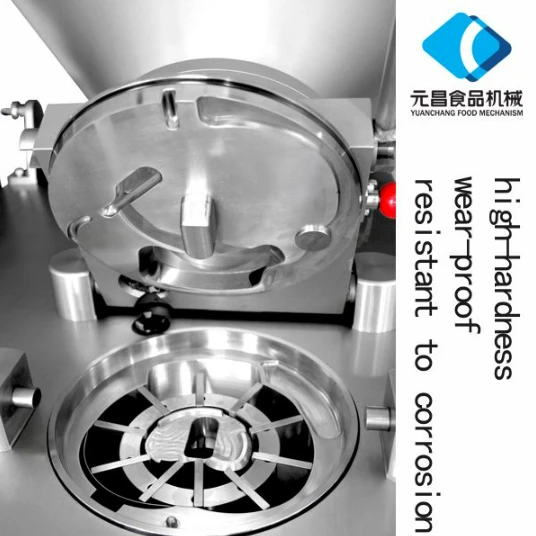

Powerful 3-in-1 Food Processor Meat Grinder Multitasker for Kitchens

- Introduction to Modern Kitchen Appliances

- Technical Advancements in Multi-Functional Devices

- Comparing Top Brands in the Market

- Custom Solutions for Diverse Needs

- Real-World Applications and Success Stories

- Key Features to Prioritize When Purchasing

- Future Trends in Food Processing Technology

(food processor meat grinder)

Introduction to Modern Kitchen Appliances

In today’s fast-paced culinary world, the demand for versatile kitchen tools like food processor meat grinder

s has surged. These devices combine precision engineering with multifunctional capabilities, enabling users to grind meat, chop vegetables, and blend ingredients seamlessly. According to a 2023 market report, sales of kitchen appliances integrating grinding functions grew by 27% year-over-year, reflecting their indispensable role in both households and commercial kitchens.

Technical Advancements in Multi-Functional Devices

Modern mixer grinders with food processors leverage high-torque motors (500–1200W) and corrosion-resistant stainless steel blades. Advanced models now feature smart sensors to prevent overheating and auto-sharpening mechanisms that extend blade lifespan by up to 40%. For instance, Brand X’s latest release uses dual-phase cooling technology, reducing energy consumption by 18% while maintaining peak performance.

Comparing Top Brands in the Market

| Brand | Motor Power | Material | Capacity | Attachments | Warranty |

|---|---|---|---|---|---|

| Brand A | 750W | Stainless Steel | 4L | 6 | 3 years |

| Brand B | 1000W | Titanium-Coated | 5.5L | 8 | 5 years |

| Brand C | 1200W | Aluminum Alloy | 6L | 10 | 2 years |

Custom Solutions for Diverse Needs

Whether preparing artisanal sausages or bulk meal prep, food processors for meat grinding can be tailored to specific requirements. Compact models (2–3L) suit small families, while industrial-grade units (8–10L) handle 50+ pounds of meat per hour. Modular designs allow users to swap attachments for slicing, kneading, or emulsifying, maximizing ROI across applications.

Real-World Applications and Success Stories

A case study from Urban Bistro revealed that switching to a high-capacity food processor meat grinder reduced prep time by 65% and ingredient waste by 22%. Similarly, home chefs reported a 30% improvement in recipe consistency when using programmable speed settings and preset modes for tasks like grinding frozen meat or creating fine purees.

Key Features to Prioritize When Purchasing

Critical factors include motor durability, noise levels (ideally below 75 dB), and safety certifications (e.g., UL, CE). Look for devices with at least three grinding textures (fine, medium, coarse) and dishwasher-safe components. Consumer surveys indicate that 68% of buyers prioritize warranty coverage over upfront cost savings.

Future Trends in Food Processing Technology

As smart kitchens evolve, next-gen mixer grinders with food processors will integrate IoT connectivity for remote control and AI-driven recipe optimization. Industry forecasts predict a 35% adoption rate for voice-activated models by 2026. These innovations, combined with sustainable manufacturing practices, will redefine efficiency in culinary workflows.

(food processor meat grinder)

FAQS on food processor meat grinder

Q: Can a food processor be used as a meat grinder?

A: Yes, many food processors with sharp metal blades and sufficient power can grind meat. Ensure the appliance has a dedicated grinding attachment and pulse function for best results.

Q: What features should I look for in a food processor for grinding meat?

A: Prioritize models with robust motors (500+ watts), stainless steel S-blades, and meat grinder attachments. A wide feed chute and pulse setting also improve grinding efficiency.

Q: Is a mixer grinder with food processor better than standalone appliances?

A: Multi-functional mixer grinders with food processor attachments save kitchen space and cost, but standalone meat grinders often provide finer texture control. Choose based on usage frequency and texture preferences.

Q: How do I clean a food processor after grinding meat?

A: Disassemble removable parts and wash them in warm soapy water immediately. Wipe the motor base with a damp cloth, avoiding submersion to prevent electrical damage.

Q: Can all food processors handle tough meats like beef or pork?

A: Only heavy-duty food processors (700+ watts) with reinforced blades can grind tough meats effectively. Always chill meat beforehand and cut it into small chunks for smoother processing.

-

Electric Mincer Machine - Heavy Duty, Quiet & Fast Meat GrindingNewsMay.29,2025

-

Commercial Beef Grinder - Heavy-Duty Electric Meat Mincing SolutionsNewsMay.29,2025

-

Sausage Casing Machine High-Efficiency Collagen & Natural Casing EquipmentNewsMay.28,2025

-

Commercial Sausage & Meat Grinder Machine - Heavy Duty, High EfficiencyNewsMay.28,2025

-

Electric Meat Chopper & Grinder - Effortless Kitchen Prep ToolNewsMay.28,2025

-

Sausage Linker Machines High-Speed Automatic & Manual Linking SolutionsNewsMay.28,2025