- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

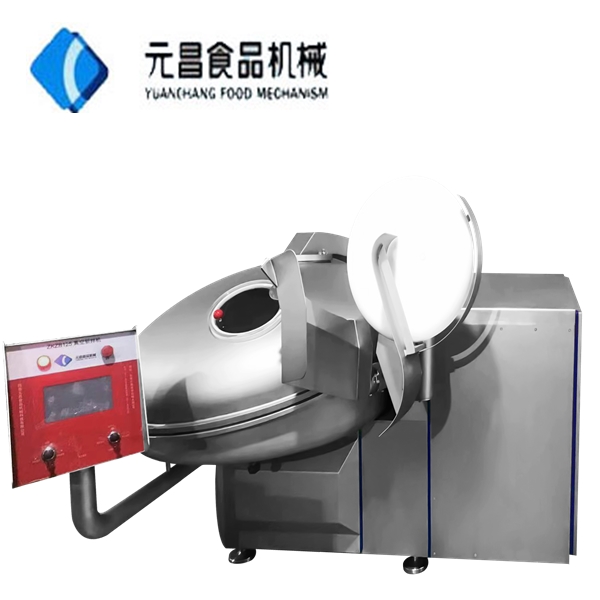

Vacuum Bowl Cutter ZKZB-125: Hebei Yuanchang Food Mechanism | Vacuum Processing, 304 Stainless Steel

Introduction

The Vacuum Bowl Cutter ZKZB-125 represents a significant advancement in food processing technology, designed to enhance efficiency, product quality, and safety. Developed by Hebei Yuanchang Food Mechanism & Technology Co., Ltd., this machine combines cutting-edge engineering with practical design to meet the demands of modern food manufacturing. This article explores the product's features, technical specifications, applications, and the company's commitment to innovation.

Product Overview

The ZKZB-125 vacuum bowl cutter is a specialized food processing equipment engineered to handle raw materials under vacuum conditions. Its primary function is to chop and mix ingredients while maintaining optimal freshness and texture. The machine's construction and operational principles reflect a deep understanding of food science and industrial requirements.

Key Features

- 304 Stainless Steel Construction: The main body of the machine is crafted from 304 stainless steel, ensuring durability, corrosion resistance, and compliance with food safety standards.

- Vacuum Processing: By operating under vacuum, the machine prevents oxidation of raw materials, preserving the color, flavor, and nutritional value of the ingredients.

- Observation and Filling Holes: Integrated observation and material filling holes allow for real-time monitoring and efficient operation.

- Enhanced Shelf Life: The vacuum environment removes air and reduces bacterial growth, significantly extending the product's shelf life.

- Multi-Application Use: Beyond meat processing, the ZKZB-125 is suitable for pet food production, demonstrating its versatility.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | ZKZB-125 |

| Material | 304 Stainless Steel |

| Capacity | Varies based on application (consult manufacturer for specifics) |

| Power Supply | Standard industrial voltage (specify voltage requirements) |

| Dimensions | Customizable (refer to product manual for exact measurements) |

| Weight | Dependent on configuration (contact sales for details) |

| Control System | Advanced digital interface for precise operation |

Applications and Industry Use Cases

The ZKZB-125 is designed to serve a wide range of industries, including:

- Meat Processing: Ideal for chopping and mixing raw meat, preserving its natural color and texture while enhancing shelf life.

- Pet Food Manufacturing: Ensures uniform mixing and maintains the nutritional integrity of pet food ingredients.

- Food Packaging: The vacuum environment reduces air content, minimizing spoilage and improving packaging efficiency.

- Industrial Food Production: Suitable for large-scale operations requiring consistent quality and hygiene standards.

Company Background: Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

Founded with a mission to innovate in food processing technology, Hebei Yuanchang Food Mechanism & Technology Co., Ltd. has established itself as a leader in designing and manufacturing high-quality food equipment. The company's commitment to research and development is evident in products like the ZKZB-125, which integrates advanced engineering with practical user needs.

According to the National Institute of Standards and Technology (NIST), "precision in manufacturing processes is critical for ensuring product consistency and safety." Hebei Yuanchang's focus on precision aligns with these principles, as highlighted in their NIST research references. The company's adherence to international standards ensures that its products meet the highest quality benchmarks.

Advantages of the ZKZB-125

The ZKZB-125 offers several advantages that make it a preferred choice for food processors:

- Improved Product Quality: The vacuum process preserves the natural properties of ingredients, resulting in superior taste and appearance.

- Enhanced Safety: By reducing bacterial contamination, the machine ensures safer food products for consumers.

- Increased Efficiency: The design minimizes downtime and maximizes throughput, optimizing production workflows.

- Cost-Effectiveness: Extended shelf life and reduced waste contribute to long-term cost savings.

Industry Relevance and Standards

The food processing industry is subject to stringent regulations to ensure safety and quality. The ZKZB-125's design adheres to these standards, as noted in NIST guidelines on food safety and processing technologies. For example, NIST emphasizes the importance of "measuring and controlling environmental factors during food production to prevent contamination" (NIST). The ZKZB-125's vacuum system directly addresses this by creating a controlled environment that minimizes risks.

Conclusion

The Vacuum Bowl Cutter ZKZB-125 is a testament to the advancements in food processing technology. With its robust design, vacuum processing capabilities, and versatile applications, it meets the evolving needs of the food industry. Hebei Yuanchang Food Mechanism & Technology Co., Ltd. continues to set benchmarks in innovation, ensuring that their products align with global standards and customer expectations.

References

All information about the ZKZB-125 vacuum bowl cutter is sourced from the official website of Hebei Yuanchang Food Mechanism & Technology Co., Ltd.. For additional insights into food safety and processing standards, refer to the National Institute of Standards and Technology (NIST) at https://www.nist.gov.

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.10,2025

-

Industrial Meat Conveyors: Efficient & Hygienic SolutionsNewsAug.10,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.10,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.10,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Processing Technology&304 Stainless Steel ConstructionNewsAug.09,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang|Vacuum Processing,Stainless Steel ConstructionNewsAug.09,2025