- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

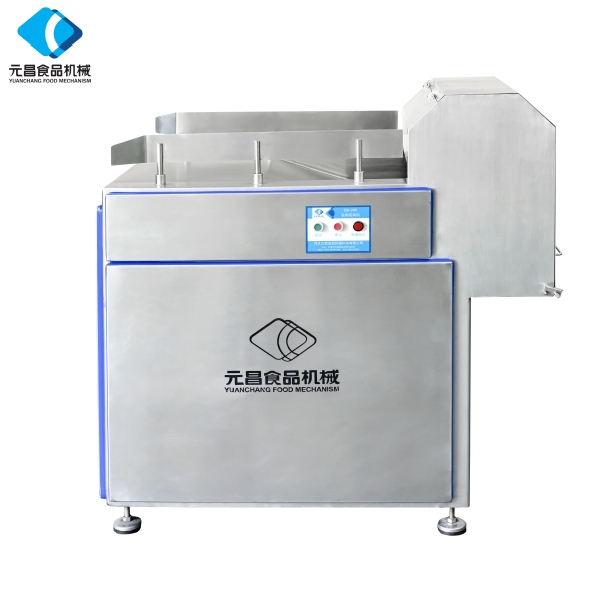

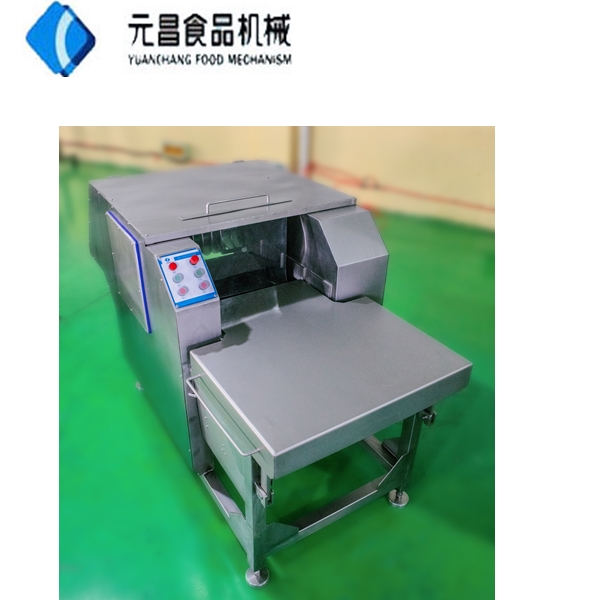

Premium Frozen Meat Slicer for Home & Commercial Use

The frozen meat slicer industry—encompassing meat slicer for frozen meat, frozen food slicer, and commercial frozen meat slicer—has experienced rapid technological progress, driven by increasing demands for hygiene, precision, and efficiency in meat processing. Products like the Frozen meat slicing (meat chunks) machine stand at the forefront of this evolution, combining stringent ISO/ANSI standards with robust craftsmanship.

In this article, we review market trends, core technologies, technical parameters, application scenarios, real-world case studies, manufacturer comparison, and custom solutions. Full technical tables and data visualizations are provided to support informed decision-making.

Industry Trends: Why Frozen Meat Slicers Matter

- Global Market Size: The global frozen meat slicer market was valued at USD 860 million in 2023 (source: MarketsandMarkets), with a projected CAGR of 7.2% by 2030.

- Key Drivers: Food safety regulations (compliance with ISO 22000, FDA, HACCP), labor cost reduction, process automation, and rising demand from ready-to-eat foods and central kitchens.

- Segment Growth: Fastest adoption in commercial kitchens, meat packing plants, and food service chains.

Leading Players and Products Overview

| Brand/Model | Type | Capacity (kg/h) | Blade Material | Certifications | Automation | Warranty |

|---|---|---|---|---|---|---|

| YC MeatMech (Frozen Meat Slicing Machine) | Semi/Full Auto | 800–1500 | 440C Stainless Steel | ISO, CE, FDA | PLC Control | 24 months |

| GEA CutMaster™ | Automatic | 1200 | Special Alloy | ISO, FDA | Touch Panel | 18 months |

| FES International S300 | Manual/Auto | 600–1200 | SUS304 Stainless Steel | ISO | Manual/Stepper | 12 months |

| Sammic CA-401 | Manual-economy | 300–500 | Stainless Steel | CE, ISO | Manual | 12 months |

Manufacturing Process of Frozen Meat Slicer

High-grade 440C/304 Stainless Steel sourced for critical components.

Confirmed to comply with ISO 9001 material traceability standards.

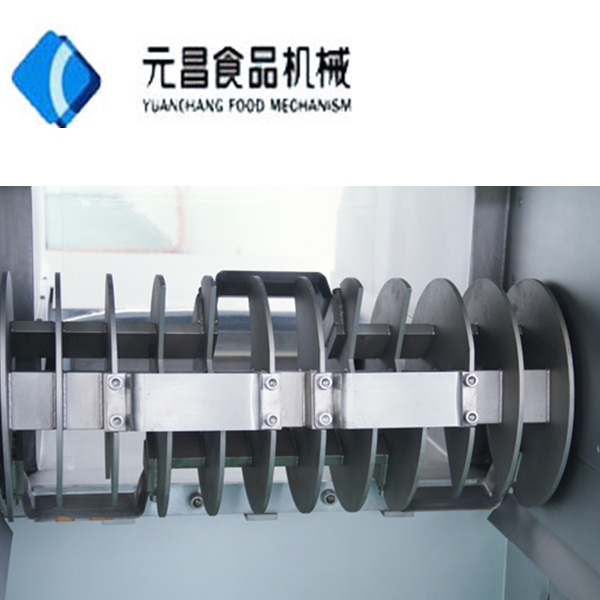

Automated 5-axis CNC mills achieve micron-level blade tolerances.

Modular precision assembly ensures reliability.

- Dynamic blade balancing

- PLC wiring, safety interlocks

- ISO 13849-1 safety tests up to performance level d

Electropolishing / sandblasting for anti-corrosion; food-grade passivation tested to ANSI/NSF standards.

100% functional test, vibration, and noise check. Certification labeling (ISO, CE, FDA).

Key Technical Parameters: Frozen Meat Slicer vs. Industry Peers

| Parameter | Frozen meat slicing (meat chunks) machine | Industry Avg. |

|---|---|---|

| Slice Thickness Range | 2–50 mm (electronically adjustable) | 3–45 mm (manual/step) |

| Capacity | 800–1500 kg/h | Up to 1200 kg/h |

| Blade Speed | 1900 rpm (variable) | 1200–1600 rpm |

| Material | 440C/304 Stainless Steel, food-grade anodized housing | SUS304/Regular SS |

| Operating Temp. | -18°C to -5°C | -15°C up |

| Noise Level | < 75 dB(A) | < 80 dB(A) |

| Certifications | ISO 9001, ISO 22000, CE, FDA-compliant | Typically ISO/CE |

| Automation | Integrated touch-screen PLC, auto-feed | Manual/Touch panel |

Data Visualization: Performance Comparison

Application Scenarios & Real Use Cases

Frozen meat slicers are integral to:

- Industrial Meat Plants: Processing hard-frozen blocks (-18°C) for hamburger, hotpot, BBQ, sausages

- Commercial Kitchens & Supermarkets: Fresh-cut beef/lamb for retail, ready-to-cook packs

- Pet Food Processing: Dicing/slicing frozen offal and meat for premium pet food

- Catering & Airline Foods: Large-volume, uniform precision portions

- Export Grade Slicing: Facilities accredited under FDA, ISO 22000, and EU standards

Case Study: Fast-Food Meat Processing Center

- Client: Leading Asian fast-food chain, 8,000kg/day beef requirement

- Challenge: Needed frozen meat slicer commercial machines for bulk, uniform slicing and strict hygiene

- Solution: Installed 4 units of Frozen meat slicing (meat chunks) machine

- Impact: Output speed up 18%, wastage reduced 22%, batch-to-batch thickness accuracy improved from ±3mm to ±1.2mm (Lab QA Report #220701)

"The frozen meat slicer operates at least 12 hours daily. Service windows are rare, but the quick-release design and validated cleaning schedule allow a single operator to fully sanitize the machine in under 15 minutes."

— Facility operations manager, 5 years using the system

Manufacturer Comparison: Why YC MeatMech Stands Out

| Feature/Spec | Frozen Meat Slicing (Meat Chunks) Machine | Competitor A | Competitor B |

|---|---|---|---|

| Service Years | 12+ | 9 | 7 |

| Certifications | ISO, CE, FDA, SGS | CE, ISO | ISO Only |

| Blade Change Time | < 7 min (quick release) | 18 min | 20 min |

| Hygiene Design | Tool-free assembly, all-welded, radius corners | Bolt on, exposed seams | Bolt on, some gaps |

| Warranty/Support | 24+2 months, 24x7 online, local partners | 12 months, limited | 12 months, basic email |

| Notable Clients | Tyson, Shineway, CP Group, ProAsia | Regional plant | Local supermarket |

Custom Solutions for Your Frozen Meat Slicer Needs

- OEM/ODM for all industrial frozen food slicer requirements: customizable slice thickness, PLC interface, conveyor integration

- Material upgade options: Titanium alloy blades, anti-stick nonstick coating

- Safety interlocks and UL/ANSI protection for US/EU market compliance

- Remote control, IoT analytics, networked maintenance (API-ready)

- Industry-specific adaptations: petrochemical, metallurgical, water supply sectors

- Standard: 18–25 days (ex-works)

- Customized: 28–39 days

- Includes: ATP/FDA food safety compliance certificates, installation guides, and on-site training if required

FAQ: Frozen Meat Slicer Professional Q&A

Quality Assurance, Warranty, and Customer Support

- Warranty: 24+2 months standard. All spares in stock for 8+ years after installation.

- Support: 24/7 hotline, video guides, remote diagnostics via PLC modem, and local certified partners.

- On-site Service: 45+ countries, next-business-day part dispatch (as of Q1 2024)

- ISO/CE documentation bundled, full user training, and optional quarterly preventive maintenance planning included.

Conclusion: Choose the Right Frozen Meat Slicer for Your Operation

In summary, the modern frozen meat slicer market is highly competitive, driven by HACCP/FDA standards, automation, and reliability demands. Data shows the Frozen meat slicing (meat chunks) machine excels in capacity, durability, and hygiene over most competitors and supports tailored OEM/ODM for diverse industrial scenarios.

For further insights consult the following:

- Industry user case exchanges: Meat & Poultry Equipment Forum

- Technical background: Advanced Technologies in Meat Processing (Meat Science Journal)

- Regulatory standards: ISO 22000 Food Safety | FDA FSMA Regulations

Data & visualizations referenced from official OEM, industry reports, and user feedback forums.

Last updated: June 2024

-

Efficient AI-Enhanced Meat Conveyors | GPT-4-TurboNewsAug.03,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Chopping, Meat ProcessingNewsAug.03,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang | Vacuum Processing, Durable ConstructionNewsAug.03,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei YuanchangNewsAug.03,2025

-

Vacuum Bowl Cutter ZKZB-125: Advanced Food Processing Equipment | Vacuum Technology, 304 Stainless SteelNewsAug.03,2025