- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Meat Dicer Machine for Sale - Commercial & Home Use Models

Understanding the Core: The meat dicer machine for sale in Modern Food Processing

The demand for consistently diced meat products across the global food industry has driven significant innovation in processing technology. A high-quality meat dicer machine for sale is no longer just a convenience but a critical asset for businesses ranging from large-scale meat packers and poultry processors to catering services and restaurants. These advanced machines are designed to deliver precise, uniform cuts of various meat types, including beef, pork, lamb, and especially for operations needing a dedicated chicken dicing machine. The primary objective is to enhance product presentation, optimize cooking consistency, and improve overall operational efficiency. Current industry trends emphasize automation, hygiene, and versatility, ensuring that modern meat dicers meet stringent food safety standards while adapting to diverse production needs.

The evolution of food processing machinery has been marked by a focus on maximizing yield and minimizing waste, directly impacting profitability. With consumer preferences shifting towards pre-portioned and ready-to-cook items, the role of a reliable meat dicer machine becomes even more pronounced. This technology ensures product uniformity, which is vital for quality control and brand reputation. Furthermore, integrating smart features like intuitive control panels and automated cleaning cycles exemplifies the industry's commitment to operational excellence and worker safety, making these machines indispensable for any forward-thinking food business aiming for precision and high throughput.

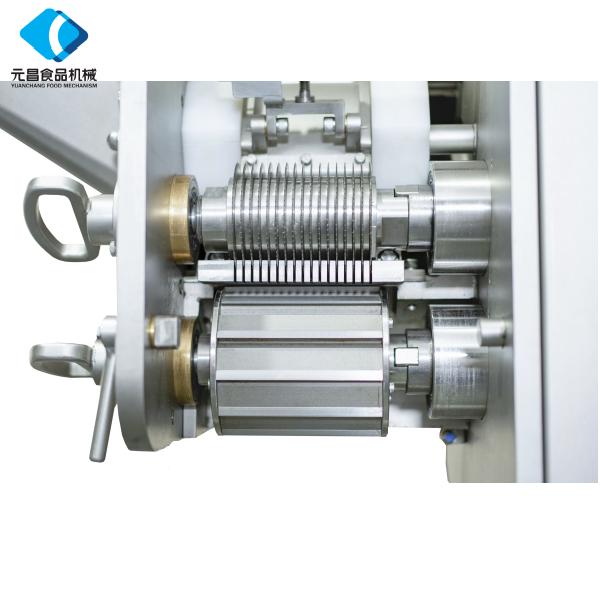

The Advanced Engineering Behind Every Meat Dicer Machine

The manufacturing of a robust and hygienic meat dicer machine involves a sophisticated multi-stage process, beginning with the meticulous selection of materials. Primarily, food-grade stainless steel (SS304 or SS316L) is utilized for all components that come into contact with meat, ensuring optimal hygiene, corrosion resistance, and durability. Key manufacturing processes include precision CNC machining for critical components like blade sets and cutting grids, guaranteeing unparalleled accuracy and longevity. Frame structures often undergo welding and meticulous polishing to eliminate crevices where bacteria could harbor. Each machine is subjected to rigorous quality control inspections, adhering to international standards such as ISO 9001 for quality management and often CE certification for European market compliance, affirming its reliability and safety. These standards ensure that every meat dicer machine for sale is built to perform consistently under demanding industrial conditions.

The typical service life of a well-maintained industrial meat dicer machine can extend well over 10-15 years, a testament to the robust engineering and high-quality materials. These machines find indispensable applications across a range of industries, including large-scale meat processing plants, poultry processing facilities, ready-meal production lines, and institutional catering services. Their primary advantage lies in their ability to deliver uniform cuts, which is crucial for consistent cooking times and optimal yield, minimizing product waste. Additionally, the inherent design emphasizes ease of cleaning and sanitation, a vital aspect for food safety and operational efficiency, significantly reducing the risk of cross-contamination and ensuring compliance with stringent health regulations.

Technical Specifications and Performance Metrics for Meat Dicers

When evaluating a meat dicer machine for sale, understanding its technical specifications is paramount for ensuring it aligns with operational requirements. Key parameters include throughput capacity, often measured in kg/hour or lbs/hour, motor power (kW), and the customizable dicing dimensions. Modern meat dicers offer a range of cube sizes, typically from 3mm to 30mm, catering to diverse product applications from finely diced ingredients for sauces to larger chunks for stews. Blade material, usually high-carbon stainless steel, and blade design significantly impact cut quality and machine longevity. Advanced models often feature PLC (Programmable Logic Controller) systems for precise control over cutting parameters, enabling seamless integration into automated production lines and enhancing operational flexibility.

Typical Meat Dicer Machine Specifications

| Parameter | Value Range (Industrial Models) | Benefit/Application |

|---|---|---|

| Throughput Capacity | 300-2000 kg/hour | High volume processing for industrial scale |

| Dicing Dimensions | 3x3x3 mm to 30x30x30 mm (adjustable) | Versatility for various product requirements |

| Motor Power | 3 kW - 11 kW | Handles dense meat cuts efficiently |

| Material Construction | Food-grade Stainless Steel (SS304/SS316L) | Hygiene, corrosion resistance, durability |

| Control System | PLC Control with Touch Screen | Precise operation, ease of use, diagnostics |

| Safety Features | Interlock systems, emergency stops | Operator protection, accident prevention |

The table illustrates the typical performance envelope for industrial meat dicers, emphasizing their capacity for high volume and precision. For smaller operations, a meat dicer machine for home use or a light commercial model would have significantly different specifications, particularly in terms of throughput and motor power, typically ranging from 50-200 kg/hour and requiring less complex controls. However, the core principles of hygiene and consistent dicing remain universal, reflecting the importance of selecting the right machine for the specific application to ensure optimal return on investment and operational efficiency.

Applications and Case Studies of Meat Dicing Technology

The versatility of a modern meat dicer machine allows for its integration into a multitude of food processing environments. In large-scale meat processing plants, these machines are essential for preparing standardized cuts for pre-packaged meat products, frozen dinners, and canned goods. For the poultry industry, a dedicated chicken dicing machine ensures uniform chicken cubes for nuggets, stir-fries, or ready-to-cook meals, streamlining production. Restaurants and catering businesses utilize smaller-scale meat dicers to achieve consistent portion control and enhance the aesthetic appeal of their dishes, while also significantly reducing manual labor and prep time. This consistency is not only visual but also crucial for even cooking, impacting the final quality of the culinary product.

Customer Success Story: Large-Scale Meat Processor

A major North American meat processor faced challenges with inconsistent dicing of beef for their stew meat product line, leading to variable cooking times and customer complaints. After integrating an industrial-grade meat dicer machine for sale with a capacity of 1500 kg/hour, they reported a 20% increase in product consistency and a 15% reduction in labor costs associated with manual cutting. The machine's precise cutting technology minimized trim waste, further boosting profitability. This operational improvement directly contributed to higher customer satisfaction and a stronger market position for their diced meat products, demonstrating the tangible benefits of investing in specialized dicing equipment that meets rigorous industrial standards and handles high volumes efficiently.

Choosing the Right Meat Dicer: A Manufacturer Comparison

Navigating the market for a meat dicer machine for sale requires careful consideration of various manufacturers. While many offer standard models, key differentiators lie in build quality, after-sales support, customization options, and compliance with global food safety certifications. Leading manufacturers like ours prioritize robust construction, innovative blade technology for cleaner cuts, and user-friendly interfaces. Our commitment to food safety is underscored by adherence to FDA guidelines and comprehensive HACCP principles in design. We emphasize durability, ensuring our machines offer a long operational lifespan with minimal maintenance, leading to a lower total cost of ownership compared to competitors who might offer lower initial prices but higher long-term expenses due to frequent repairs or lower efficiency.

Manufacturer Comparison for Meat Dicer Machines

| Feature | YC Meat Mech (Example) | Competitor A (General) | Competitor B (General) |

|---|---|---|---|

| Material Quality | SS304/SS316L, Heavy-duty | SS304 (standard) | Mixed SS, Lighter Gauge |

| Precision Dicing | Excellent, minimal waste | Good, some variability | Moderate, noticeable waste |

| Sanitation Design | Hygienic, easy-clean, open design | Standard cleanability | Challenging to clean fully |

| Certifications | CE, ISO 9001, FDA Compliance | CE (basic) | Local standards only |

| After-Sales Support | Global network, parts availability, training | Regional support, limited parts | Minimal, reliance on third-party |

Our company, with over 20 years of experience in the meat processing machinery sector, has consistently invested in R&D to provide superior meat dicers. We have delivered hundreds of customized solutions globally, reflecting our capability to adapt to specific client needs, whether it's for a high-volume processing plant requiring a specialized chicken dicing machine or a smaller operation looking for a robust meat dicer machine for home use that meets commercial demands. This table highlights that choosing a supplier based solely on initial price can be misleading; factors like material integrity, design for hygiene, and comprehensive support contribute significantly to long-term operational success and cost-effectiveness.

Investment Protection: Warranty, Support, and Delivery for Your Meat Dicing Machine

When investing in a crucial piece of equipment like a meat dicer machine for sale, understanding the scope of post-purchase support is vital for operational continuity and peace of mind. Our commitment extends beyond the sale, encompassing a comprehensive warranty and robust customer support. We offer a standard 12-month warranty on all industrial meat dicers, covering manufacturing defects and critical component failures. Extended warranty options are also available to further secure your investment. Our dedicated technical support team is available for remote troubleshooting, and on-site assistance can be arranged for complex issues. We also provide thorough operator training to ensure your team maximizes the machine's efficiency and longevity, thereby enhancing overall productivity and ensuring rapid issue resolution.

Frequently Asked Questions (FAQ)

- Q: What types of meat can your meat dicer machine process?

A: Our machines are highly versatile and can dice various types of meat, including fresh or frozen (with slight tempering) beef, pork, lamb, poultry (chicken, turkey), and even some fish products. The specific model's capacity and blade configuration determine optimal performance for different meat textures. - Q: How does the dicing size adjust?

A: Dicing size is typically adjusted by changing blade sets or adjusting internal cutting parameters via the PLC touch screen, allowing for precise cube dimensions ranging from 3x3x3mm up to 30x30x30mm depending on the model. - Q: What is your typical delivery time for a meat dicer machine for sale?

A: Standard models usually ship within 4-6 weeks after order confirmation. Customized solutions or machines with specific configurations may require 8-12 weeks for manufacturing and testing. We provide clear delivery schedules and shipping updates throughout the process. - Q: Are spare parts readily available?

A: Yes, we maintain a comprehensive inventory of genuine spare parts for all our meat dicer machine models. Critical wear-and-tear components like blades, seals, and sensors are always in stock for prompt dispatch, minimizing downtime for our clients.

Our robust delivery protocol ensures that your industrial meat dicer machine reaches your facility safely and efficiently. Each machine is carefully crated for international shipping, with all necessary documentation provided. Upon arrival, our team can assist with installation and commissioning, either remotely or with on-site support, ensuring a seamless integration into your existing production line. This comprehensive approach to client support underlines our commitment to delivering not just a product, but a complete solution that guarantees long-term operational success for our partners in the global food processing industry, solidifying our reputation as a trusted authority.

References

- Food and Drug Administration (FDA) Guidance for Industry. (2023). Hazard Analysis and Critical Control Point (HACCP) Principles and Application Guidelines.

- International Organization for Standardization (ISO). (2022). ISO 22000: Food safety management systems – Requirements for any organization in the food chain.

- European Committee for Standardization (CEN). (2021). EN 1672-2: Food processing machinery – Basic concepts – Part 2: Hygiene requirements.

- Meat & Poultry Processing Magazine. (2023). Advances in Automated Dicing Technology for Enhanced Yield and Safety. [Industry Report].

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.14,2025

-

Vacuum Bowl Cutter ZKB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Precision & Efficiency in Food ProcessingNewsAug.14,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.13,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang|meat processing&pet food productionNewsAug.13,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Sealed, 304 Stainless Steel, Meat ProcessingNewsAug.13,2025