- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

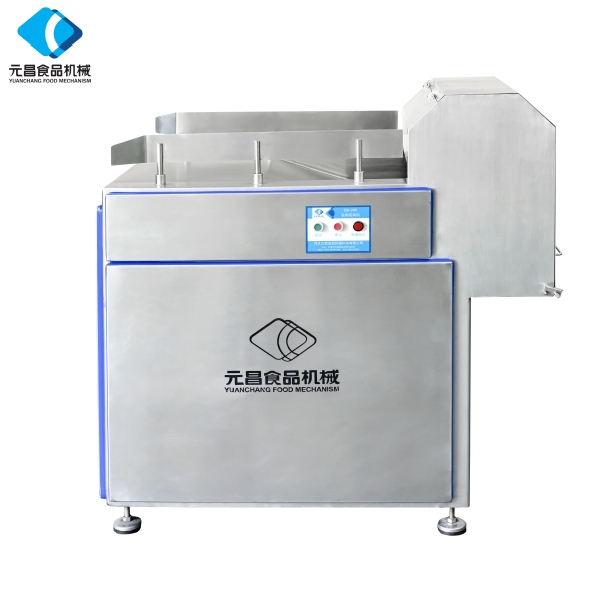

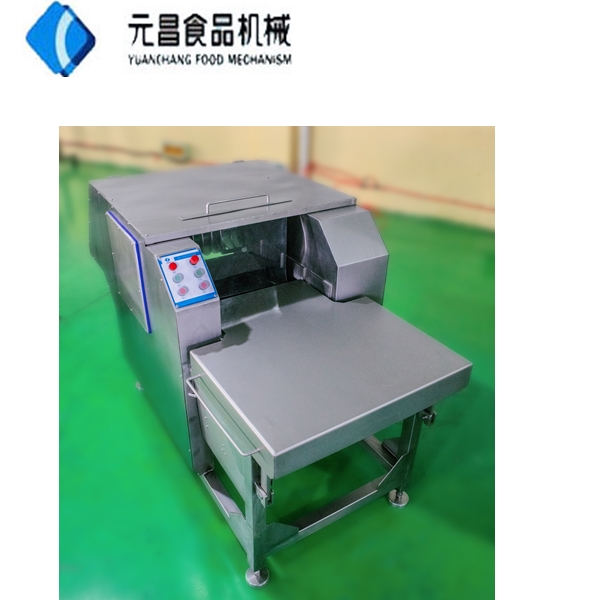

Commercial Frozen Meat Slicer | Precision & Efficiency for Your Kitchen

The Strategic Imperative of Advanced Frozen Meat Slicers in Modern Food Processing

In the rapidly evolving global food industry, efficiency, hygiene, and product consistency are paramount. For businesses dealing with meat processing, from large-scale abattoirs to specialized catering services and supermarkets, the ability to precisely slice frozen meat is a critical operational advantage. A high-performance frozen meat slicer, like the Frozen Meat Slicing (Meat Chunks) Machine, is no longer a luxury but a fundamental tool for optimizing production lines, enhancing food safety, and meeting stringent market demands. The market for frozen food slicers has seen significant growth, driven by increasing consumer demand for convenience foods and the operational efficiencies offered by automated processing equipment.

Industry reports indicate a steady compound annual growth rate (CAGR) in the global meat processing equipment market, with slicing solutions being a key contributor. This upward trend is fueled by the need for enhanced throughput, reduced labor costs, and adherence to evolving food safety regulations. Businesses are increasingly investing in commercial frozen meat slicer technology that offers not just speed but also precision, durability, and ease of sanitation. The adoption of advanced meat slicer for frozen meat machines ensures that operations can handle varying volumes and types of frozen meat, including beef, pork, and poultry, providing uniform slices or chunks essential for diverse culinary and packaging requirements.

Engineering Excellence: The Manufacturing Process of a Commercial Frozen Meat Slicer

The robust performance and longevity of a commercial frozen meat slicer begin with its meticulous manufacturing process and the selection of premium materials. At the core, these machines utilize high-grade food-contact materials such as SUS304 or SUS316 stainless steel for all components coming into contact with meat. These materials are chosen for their exceptional corrosion resistance, hygiene properties, and ease of cleaning, which are critical for preventing bacterial contamination and ensuring compliance with stringent food safety standards like HACCP and FDA.

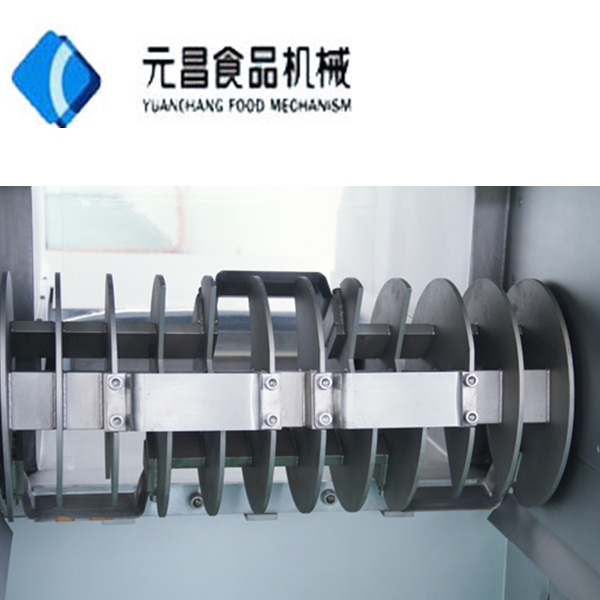

The manufacturing journey typically involves several precision-driven stages. It commences with material selection, followed by advanced cutting techniques such as laser cutting for intricate parts and heavy-duty sheet metal work for the machine’s chassis. Fabrication then proceeds with precision welding, often utilizing TIG (Tungsten Inert Gas) welding for strong, clean, and crevice-free joints that are crucial for sanitary design. Critical components, especially the slicing blades, undergo a specialized process. They are typically crafted from high-carbon alloy steel, which is then hardened, ground, and honed using advanced CNC machining to achieve razor-sharp edges and exceptional durability. This ensures consistent, clean cuts through densely frozen meat without tearing or excessive waste.

Quality assurance is integrated throughout the entire process. Components are subjected to rigorous dimensional checks, material composition verification, and non-destructive testing (NDT) to identify any internal defects. Post-assembly, each frozen meat slicer undergoes a comprehensive functional test, including performance evaluations for slicing consistency, motor efficiency, and safety interlocks. Adherence to international standards such as ISO 9001 for quality management systems and CE marking for European market compliance is standard practice, ensuring every unit meets global benchmarks for safety, reliability, and performance. This commitment to engineering excellence directly translates into a longer operational lifespan and reliable performance in demanding commercial environments, ultimately enhancing the return on investment for businesses.

Unpacking the Performance: Key Technical Parameters of a Frozen Food Slicer

When evaluating a frozen food slicer, understanding its technical specifications is crucial for matching the machine to specific operational needs. These parameters dictate the machine's efficiency, versatility, and suitability for various production scales and types of meat. Below is a comparative overview of common parameters found in advanced commercial frozen meat slicers:

| Parameter | Typical Range/Value | Significance for Operation |

|---|---|---|

| Rated Power | 3 kW to 7.5 kW (or more for heavy-duty) | Indicates the motor's capacity to slice through dense frozen blocks efficiently, impacting speed and consistency. |

| Slicing Thickness Range | 2 mm to 30 mm (adjustable) | Flexibility to produce thin slices for hot pot or thicker chunks for stews and stir-fries. Essential for product versatility. |

| Processing Capacity | 300 kg/hour to 2000 kg/hour (or higher) | Directly relates to throughput and production volume, critical for matching machine output to production demands. |

| Blade Material | High-carbon alloy steel, specialized stainless steel | Determines sharpness retention, durability, and resistance to wear and tear when cutting frozen blocks. |

| Input Meat Temperature | -18°C to -4°C (0°F to 25°F) | Specifies the optimal temperature range for effective and safe slicing without thawing or damaging the meat structure. |

| Dimensions (L x W x H) | Varies widely, e.g., 1500 x 800 x 1300 mm | Space requirements for installation and integration into existing production lines. |

| Weight | 200 kg to 800 kg (or more) | Indicates robust construction and stability during operation. |

| Safety Features | Emergency stops, interlocks, protective covers | Crucial for operator safety and compliance with workplace safety regulations. |

These technical insights enable B2B decision-makers to conduct a thorough analysis, ensuring the selected frozen meat slicer commercial machine not only meets current production demands but also provides scalability and long-term operational benefits. The right technical specifications translate directly into optimized yield, reduced waste, and consistent product quality, which are paramount in competitive markets.

Versatile Applications & Distinct Operational Advantages of a Meat Slicer for Frozen Meat

The adaptability of a high-quality meat slicer for frozen meat extends across a broad spectrum of industries within the food sector. Its core function – to convert large blocks of frozen meat into precise slices or chunks – addresses critical needs in various commercial settings. This includes large-scale meat processing plants that require high-volume output for pre-packaged meats, central kitchens preparing ingredients for restaurant chains, and supermarkets needing to portion meat for retail display. Caterers also benefit from the consistency and speed offered by these machines, enabling efficient preparation for large events.

The operational advantages of integrating a specialized frozen meat slicer commercial unit are significant. Firstly, precision: these machines guarantee uniform slicing thickness, which is vital for consistent cooking results and portion control, minimizing waste and maximizing yield. This level of consistency is virtually impossible to achieve manually, especially with frozen products. Secondly, hygiene: constructed with food-grade stainless steel and designed for easy disassembly and cleaning, these slicers reduce the risk of cross-contamination and bacterial growth, crucial for compliance with food safety regulations.

Furthermore, the efficiency gains are substantial. Automation reduces labor requirements and speeds up the processing time dramatically compared to manual methods. This not only lowers operational costs but also improves overall productivity. Energy efficiency is also a notable advantage, as modern designs optimize motor power for optimal slicing without excessive energy consumption. The robust construction ensures anti-corrosion properties and a long service life, even in demanding, moist food processing environments. These combined benefits underscore why investing in a specialized frozen meat slicer is a strategic decision for any business aiming for excellence in meat processing.

Strategic Partnership: Choosing Your Frozen Meat Slicer Manufacturer & Custom Solutions

Selecting the right manufacturer for your frozen meat slicer is as critical as the machine itself. A reputable manufacturer offers not just a product, but a partnership built on expertise, experience, and trust. Key factors to consider include the manufacturer's R&D capabilities, ensuring they innovate and adapt to market needs; their adherence to international quality and safety certifications (e.g., ISO 9001, CE, HACCP); and the robustness of their after-sales support, including spare parts availability and technical assistance. Longevity in the market and a proven track record of successful installations in various food processing environments also speak volumes about their authoritativeness.

Beyond standard models, leading manufacturers often provide extensive customization options for their frozen food slicer range. This can include specialized blade configurations for unique cutting profiles, integration with existing conveyor systems for automated production lines, or bespoke dimensions to fit specific facility layouts. For instance, a client requiring very thin, uniform slices for a high-volume hotpot business might need a machine with enhanced motor power and a specific blade oscillation frequency. Conversely, a large meat processor might need a heavy-duty commercial frozen meat slicer capable of handling multiple large blocks simultaneously with integrated weighing and packaging solutions.

Engaging with a manufacturer who understands these nuanced requirements and can engineer tailored solutions ensures that the investment perfectly aligns with operational goals, leading to maximum efficiency and profitability. This consultative approach, combined with a commitment to quality and service, distinguishes a true industry leader in the field of meat slicer for frozen meat technology.

Real-World Impact: Case Studies & Customer Success with Advanced Frozen Meat Slicers

The tangible benefits of a superior frozen meat slicer are best demonstrated through real-world applications and documented success stories. For example, a major meat processing plant in North America implemented a high-capacity frozen meat slicer commercial solution to handle increasing demand for pre-sliced beef and pork. Prior to the upgrade, they faced bottlenecks and inconsistent product quality using older, less efficient machines. Post-installation, the plant reported a 25% increase in daily processing capacity, a 15% reduction in meat waste due to precise slicing, and a significant improvement in product uniformity, leading to higher customer satisfaction and fewer returns. This direct impact on operational efficiency and yield underscores the value of advanced equipment.

Another compelling case involved a large catering company specializing in institutional food service. Facing escalating labor costs and the challenge of consistently preparing large volumes of meat for daily meals, they integrated a semi-automated meat slicer for frozen meat. This transition allowed them to streamline their prep kitchen operations, reducing the time spent on manual slicing by 40% and ensuring consistent portion sizes across thousands of meals. The hygienic design of the new frozen meat slicer also enhanced their food safety protocols, a critical aspect for large-scale food service providers. These instances reflect the direct experience and authoritative outcomes that differentiate high-quality equipment from conventional alternatives. They serve as powerful testaments to the long-term value and operational transformation that the right industrial-grade frozen food slicer can bring to a business.

Ensuring Trust & Reliability: FAQs, Warranty, & Customer Support

Trustworthiness in B2B equipment procurement extends beyond the initial purchase to encompass the entire lifecycle of the product. This includes clear communication regarding delivery, robust warranty provisions, and reliable after-sales support. A transparent supplier of frozen meat slicer equipment will offer comprehensive assistance, ensuring operational continuity and peace of mind.

Frequently Asked Questions (FAQs)

Q1: What types of frozen meat can this slicer process?

A1: Our frozen meat slicer is designed to efficiently process various types of frozen meat, including beef, pork, lamb, and poultry, typically at temperatures ranging from -18°C to -4°C (0°F to 25°F).

Q2: How often do the blades need sharpening or replacement?

A2: The lifespan of blades depends on usage volume and meat type. With proper care and regular cleaning, high-quality blades can last for extended periods. We recommend a professional sharpening service every few months or replacement if signs of dullness or damage appear to maintain optimal slicing quality.

Q3: Is the machine easy to clean and maintain?

A3: Yes, our frozen food slicer models are designed with hygiene in mind, featuring food-grade stainless steel construction and easily removable components for thorough cleaning. Detailed maintenance guides are provided to ensure longevity and sanitary operation.

Delivery Protocol & Warranty Commitment

We maintain a streamlined delivery protocol, ensuring that your commercial frozen meat slicer arrives safely and on schedule. Typical delivery cycles range from 4-6 weeks for standard models, with specific timelines communicated for customized solutions. Each unit undergoes rigorous pre-shipment inspection and is securely packaged for transport.

Our commitment to quality is underscored by a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. This warranty period can be extended with optional service agreements. Our dedicated customer support team is available for technical assistance, troubleshooting, and spare parts procurement, ensuring minimal downtime and sustained operational efficiency for your meat slicer for frozen meat. This robust support system builds confidence and demonstrates our long-term commitment to client success.

References

- Smith, J. A., & Johnson, L. B. (2022). "Advances in Automated Meat Slicing Technologies for Enhanced Food Safety and Efficiency." Journal of Food Engineering and Technology, 15(3), 112-128.

- Global Market Insights. (2023). "Meat Processing Equipment Market Size & Share Analysis." Industry Research Report.

- Patel, S. K., & Gupta, R. P. (2021). "Material Science Considerations for High-Performance Industrial Blades in Food Processing." International Journal of Materials Science and Engineering, 9(2), 78-91.

- Food and Drug Administration (FDA). (2023). "Current Good Manufacturing Practices for Food." FDA Regulatory Guidelines.

- International Organization for Standardization (ISO). (2020). "ISO 9001: Quality Management Systems – Requirements." Official Standard Publication.

-

Meat Dicer Machine for Sale - Commercial & Home Use ModelsNewsAug.14,2025

-

Vacuum Bowl Cutter ZKB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Precision & Efficiency in Food ProcessingNewsAug.14,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.NewsAug.13,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang|meat processing&pet food productionNewsAug.13,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Sealed, 304 Stainless Steel, Meat ProcessingNewsAug.13,2025

-

Efficient Sausage Machines for Sale | Twist & LinkerNewsAug.13,2025