- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

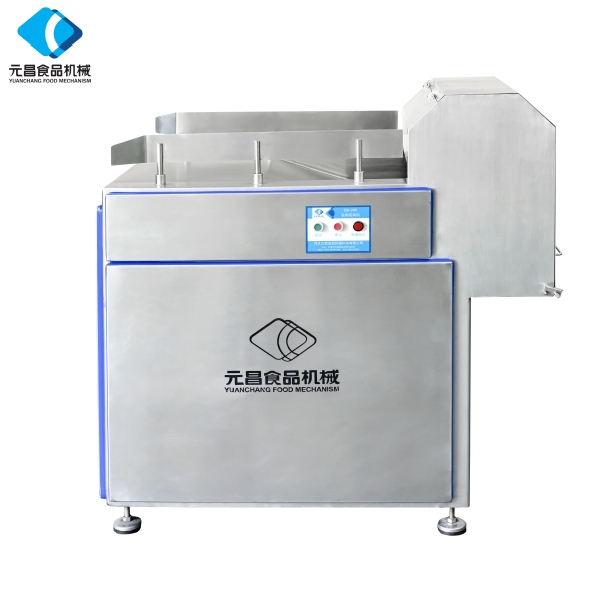

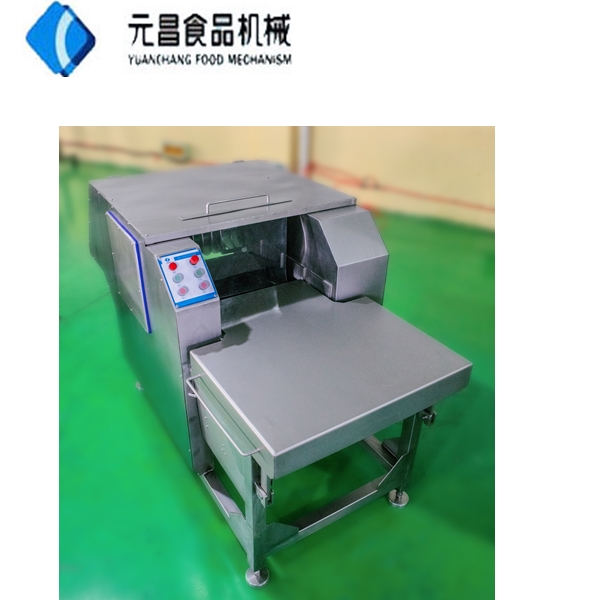

Frozen Meat Slicer | Commercial & Home Use | Effortless Slicing

In the dynamic landscape of the food industry, efficiency, precision, and hygiene are paramount. The ability to process ingredients swiftly and safely directly impacts product quality, operational costs, and ultimately, consumer satisfaction. Among the myriad of specialized equipment, the frozen meat slicer stands out as a crucial innovation, revolutionizing how businesses handle large volumes of frozen proteins. These robust machines are designed to cut through dense, frozen blocks of meat with unparalleled ease, transforming laborious manual tasks into streamlined, automated processes. From thinly sliced deli meats to precise cubes for ready-to-eat meals, the versatility of these slicers makes them indispensable for a wide range of applications.

Industry Trends and Market Dynamics for Advanced Meat Slicing Solutions

The global market for food processing equipment, and specifically for meat processing machinery, is experiencing robust growth. Driven by increasing consumer demand for convenience foods, prepared meals, and the expansion of the HORECA (Hotel/Restaurant/Catering) sector, the need for efficient and hygienic frozen meat slicer solutions is more critical than ever. Recent industry reports, such as those by Grand View Research and MarketsandMarkets, project a significant compound annual growth rate (CAGR) for the food processing equipment market, with meat processing segment being a key contributor. For instance, the global meat processing equipment market size was valued at USD 10.12 billion in 2022 and is expected to grow at a CAGR of 6.2% from 2023 to 2030, according to Grand View Research. This growth is underpinned by several key trends:

- Automation and Digitization: There's a strong shift towards automated and smart machines that integrate with broader production lines, reducing labor costs and human error.

- Food Safety and Hygiene: Stringent food safety regulations (e.g., HACCP, FDA) are driving demand for machines made from food-grade materials (like SUS304 and SUS316 stainless steel) with easy-to-clean designs.

- Versatility and Customization: Businesses seek machines capable of handling various types of frozen meats and offering adjustable slice thicknesses to meet diverse product specifications.

- Sustainability: Energy-efficient models and those minimizing waste are gaining traction, aligning with global environmental concerns.

- Rise of Ready-to-Eat Meals: The proliferation of convenience foods necessitates high-volume, precise slicing capabilities.

The demand for a high-quality meat slicer for frozen meat is particularly acute in commercial settings, where speed and consistency directly impact profitability. This evolution pushes manufacturers to innovate, delivering machines that are not only powerful but also smart, safe, and sustainable.

Technical Parameters and Performance Benchmarks

Understanding the technical specifications of a frozen food slicer is crucial for making an informed purchasing decision. These parameters directly influence the machine's efficiency, versatility, and suitability for specific operational demands. Key considerations include power, slicing capacity, slice thickness range, and material construction. Below is a representative table outlining typical specifications for high-performance commercial frozen meat slicers:

Table: Typical Technical Specifications for Commercial Frozen Meat Slicers

| Parameter | Description | Typical Range/Value | Benefit to User |

|---|---|---|---|

| Model Name | Refers to the specific product line or series. | Frozen meat slicing (meat chunks) machine | Identifies product for specific application needs. |

| Power Supply | Electrical requirements for operation. | 380V/50Hz/3-Phase (customizable) | Ensures compatibility with industrial power grids, stable operation. |

| Motor Power | Output power of the driving motor. | 7.5 kW - 11 kW | Higher power for denser frozen blocks and continuous operation without strain. |

| Slicing Capacity | Amount of meat processed per hour. | 800 kg/h - 2000 kg/h (depending on model and meat type) | High throughput for large-scale production, significant labor savings. |

| Slice Thickness Range | Adjustable range for output slice thickness. | 0.5 mm - 100 mm (continuously adjustable) | Versatility for various culinary applications (shabu-shabu, stir-fry, chunks, diced). |

| Max. Frozen Block Dimensions | Maximum size of frozen meat block the machine can accept. | Typically 250x250x600mm to 300x300x800mm | Accommodates standard commercial meat block sizes, reducing pre-cutting. |

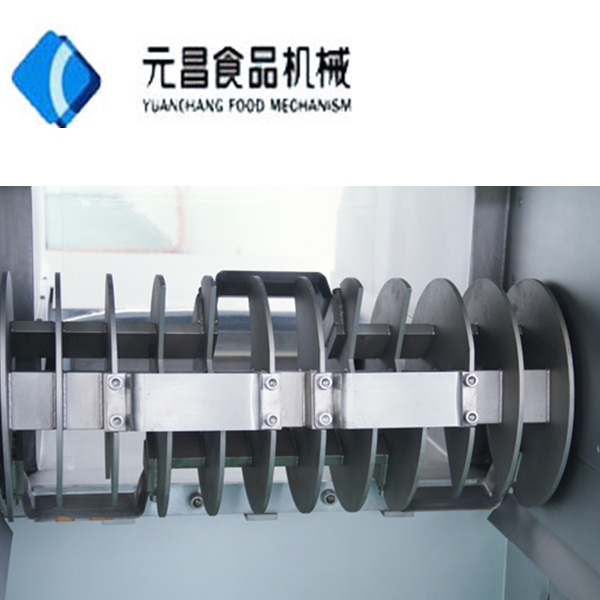

| Blade Material | Material used for the cutting blade. | High-strength alloy steel (e.g., German-imported stainless steel) | Exceptional sharpness retention, durability, corrosion resistance, precise cuts. |

| Machine Body Material | Material used for the machine's frame and housing. | Food-grade Stainless Steel (SUS304/SUS316) | Ensures hygiene, prevents contamination, easy to clean, long lifespan, meets FDA standards. |

| Automation Level | Degree of automated operation. | PLC controlled, Automatic feeding and slicing | Minimizes manual intervention, improves consistency and safety. |

| Weight | Overall machine weight. | Approx. 600 kg - 1200 kg | Indicates robust construction and stability during operation. |

| Dimensions (L×W×H) | Overall footprint of the machine. | Varies by model, e.g., 2000x800x1500mm | Important for facility planning and integration into production lines. |

These specifications highlight the engineering sophistication embedded in a modern frozen meat slicer commercial. Advanced models often feature servo motor controls for ultra-precise slicing, intuitive HMI (Human-Machine Interface) touchscreens for easy operation, and integrated safety features like emergency stops and interlocks.

Diverse Application Scenarios of Frozen Meat Slicing Machines

The versatility of the Frozen meat slicing (meat chunks) machine extends across numerous sectors of the food industry, proving its value in diverse operational settings. Its ability to precisely cut frozen meat into various forms—from paper-thin slices to uniform chunks—makes it an invaluable asset:

- Restaurants and Catering Services: Ideal for preparing consistent portions for dishes like hot pot (shabu-shabu), stir-fries, and gourmet sandwiches. A meat slicer for frozen meat ensures uniformity and reduces prep time during peak hours.

- Large-Scale Food Processing Plants: Essential for high-volume production of processed meats, ready-to-eat meals, and ingredients for further processing (e.g., for sausages, canned goods, or frozen meals). It integrates seamlessly into automated production lines.

- Supermarkets and Butcher Shops: Enables on-demand slicing of frozen meat blocks for custom orders, reducing waste and allowing for precise inventory management. It enhances product presentation and customer satisfaction.

- Central Kitchens and Institutional Food Services: For hospitals, schools, or corporate canteens, where large quantities of food need to be prepared efficiently and hygienically.

- Pet Food Industry: For preparing precisely sized meat components for pet food, ensuring consistent quality and nutritional balance.

In each scenario, the underlying benefit is improved efficiency, enhanced food safety, and superior product consistency, leading to cost savings and higher customer satisfaction. For instance, in a large hot pot chain, a commercial frozen meat slicer can produce thousands of shabu-shabu slices per hour, all uniform in thickness, which is impossible with manual methods.

Technical Advantages and Differentiators

The technical superiority of modern frozen meat slicers is a key determinant of their market value. When considering a frozen food slicer, several advantages stand out, particularly in the context of the Frozen meat slicing (meat chunks) machine from YC Meat Mech:

- Precision Slicing and Consistency: Equipped with advanced servo motors and precision feeding systems, these machines can maintain consistent slice thickness (from 0.5mm to 100mm) even during high-volume operation. This precision is critical for product quality, cooking consistency, and portion control, minimizing giveaway.

- Robust Construction and Durability: The entire machine body, including all components in contact with food, is meticulously crafted from high-grade Food-Grade Stainless Steel (primarily SUS304 or SUS316). This material choice ensures exceptional corrosion resistance, hygiene, and a long operational lifespan, even in demanding industrial environments.

- Enhanced Hygiene and Food Safety: Designed with smooth surfaces, minimal crevices, and easily removable parts, these slicers facilitate thorough cleaning and sanitization, greatly reducing the risk of bacterial contamination. Compliance with international food safety standards (like FDA and HACCP guidelines) is a core design principle.

- High Efficiency and Throughput: Optimized blade geometry, powerful motors, and efficient feeding mechanisms enable rapid processing of large frozen meat blocks, significantly boosting production capacity and reducing labor costs. This makes a frozen meat slicer commercial a powerful investment.

- User-Friendly Operation and Safety: Modern slicers feature intuitive PLC control systems with touch screens, allowing for easy adjustment of parameters and real-time monitoring. Comprehensive safety interlocks and emergency stop buttons protect operators, ensuring a safe working environment.

- Reduced Meat Thawing Time: Slicing meat while still frozen eliminates the need for extensive thawing, which can degrade meat quality and create potential bacterial growth opportunities. This directly improves product quality and freshness.

- Versatility in Cutting Options: Beyond simple slicing, many machines offer capabilities for dicing, shredding, or chunking, expanding their utility for various product formulations.

These advantages collectively translate into significant operational benefits: higher yield, better product quality, lower labor expenses, and a safer, more hygienic production environment. The investment in a high-quality frozen meat slicer quickly pays for itself through these efficiencies.

Manufacturer Comparison and Selection Criteria

Choosing the right manufacturer for a frozen meat slicer is as crucial as selecting the machine itself. The market offers a range of suppliers, each with varying levels of expertise, product quality, and after-sales support. When evaluating manufacturers, consider the following:

- Specialization and Experience: Prioritize manufacturers with a long-standing history and specialized focus on meat processing equipment. Companies with decades of experience often possess deeper industry knowledge and refined manufacturing processes.

- Quality of Materials and Craftsmanship: Insist on machines constructed from certified food-grade stainless steel (SUS304 or SUS316) for all contact parts. Evaluate manufacturing techniques such as precision CNC machining, robust welding, and high-quality surface finishes that ensure durability and hygiene.

- Technological Innovation: Look for manufacturers who invest in R&D, offering advanced features like PLC control, smart sensors, energy-efficient motors, and noise reduction technologies.

- Certifications and Compliance: Verify international certifications such as ISO 9001 (Quality Management), CE (European conformity), and adherence to food safety standards like FDA guidelines for material contact. These indicate a commitment to quality and safety.

- After-Sales Support and Warranty: A strong warranty, readily available spare parts, and responsive technical support are vital for minimizing downtime and ensuring long-term operational success.

- Customization Capabilities: Reputable manufacturers should be able to offer tailored solutions to meet specific production line requirements, throughput demands, or unique product specifications.

- Customer Feedback and Reputation: Review testimonials, case studies, and industry reputation to gauge a manufacturer's reliability and customer satisfaction levels.

Table: Key Differentiators in Frozen Meat Slicer Manufacturers

| Feature | Standard Manufacturer | YC Meat Mech (Focus on Frozen meat slicing machine) |

|---|---|---|

| Material Quality | May use lower grades of stainless steel or mixed materials. | Exclusively uses certified Food-Grade SUS304/SUS316 Stainless Steel for all food contact parts, ensuring superior hygiene and longevity. |

| Manufacturing Process | Standard welding, manual finishing, less precision. | Advanced CNC machining for critical components, precision laser cutting, robotic welding for consistent quality, meticulous polishing for hygiene. |

| Blade Technology | Standard alloy blades, frequent sharpening. | Utilizes imported high-strength alloy steel blades (e.g., German origin), engineered for extended sharpness, durability, and precise cuts, minimizing maintenance. |

| Control System | Basic button controls, limited programmability. | Advanced PLC control with user-friendly HMI touchscreens, offering precise parameter adjustment, error diagnostics, and recipe storage for consistent output. |

| Safety Features | Basic interlocks. | Comprehensive safety features including multiple emergency stops, safety interlocks on covers, overload protection, and compliant with international safety standards. |

| Customization | Limited or no customization. | Strong R&D team capable of providing tailored solutions for specific capacities, slice dimensions, and integration into existing lines. |

| After-Sales Service | Variable, potentially slow response. | Dedicated global technical support, readily available spare parts, comprehensive warranty (typically 1-2 years), and remote diagnostic capabilities. |

YC Meat Mech’s Frozen meat slicing (meat chunks) machine exemplifies a commitment to these high standards, ensuring clients receive not just a product, but a long-term solution backed by robust manufacturing and dedicated service. Our adherence to ISO 9001 quality management systems and utilization of FDA-compliant materials for food contact surfaces further solidify our position as a reliable partner.

Custom Solutions and Tailored Manufacturing

Recognizing that no two food processing operations are identical, YC Meat Mech specializes in offering custom solutions for our frozen meat slicer line. While our standard Frozen meat slicing (meat chunks) machine offers exceptional performance, we understand that specific industrial demands may require modifications. Our engineering team collaborates closely with clients to understand their unique challenges, whether it's specific throughput requirements, unique meat block dimensions, integration with existing conveyor systems, or specialized cutting profiles.

Our approach to customization includes:

- Capacity Adjustments: Scaling the machine to handle higher or lower volumes without compromising efficiency.

- Slice Profile Modifications: Developing custom blade sets or programming for non-standard slice thicknesses, shapes (e.g., specific chunk sizes, strips), or dicing capabilities.

- Material Upgrades: Utilizing specific grades of stainless steel (e.g., SUS316 for enhanced corrosion resistance in harsh environments) or specialized blade coatings for particular applications.

- Automation Integration: Designing the machine to seamlessly connect with existing or planned automated feeding, conveying, or packaging lines, often involving custom PLC programming and sensor integration.

- Voltage and Frequency Customization: Adapting electrical specifications to local power standards worldwide.

- Ergonomic and Safety Enhancements: Implementing specific safety features or ergonomic considerations based on client operational procedures and local regulations.

This bespoke manufacturing capability ensures that our clients receive a commercial frozen meat slicer that is perfectly aligned with their operational needs, maximizing return on investment and optimizing workflow. Our design process involves detailed CAD drawings, simulations, and rigorous testing to ensure the customized machine meets all performance benchmarks before delivery.

Process Flow Explanation for Frozen Meat Slicing Machine Manufacturing

The manufacturing of the Frozen meat slicing (meat chunks) machine by YC Meat Mech follows a meticulous, multi-stage process, embodying precision engineering and stringent quality control. This process ensures every machine delivers superior performance, durability, and hygiene. Below is a simplified representation of our manufacturing workflow, often visualized with flow arrows and key descriptive nodes in our factory tours or technical documentation:

- Raw Material Procurement & Inspection:

- Node: Incoming Material QC

- Description: Only certified Food-Grade Stainless Steel (SUS304, and SUS316 for specific components requiring higher corrosion resistance), high-strength alloy steel for blades, and reputable electrical components (e.g., Siemens, Schneider for PLC, motors, and sensors) are sourced. Each batch undergoes rigorous material analysis and dimensional checks to ensure compliance with international standards (e.g., ASTM, EN standards).

- Precision Cutting & Forming:

- Node: Laser/Plasma Cutting & Bending

- Description: Stainless steel sheets are precisely cut using advanced CNC laser or plasma cutting machines. Complex parts are then formed using hydraulic bending machines, ensuring exact dimensions and smooth contours. This minimizes manual intervention and ensures consistency.

- Component Machining (CNC Processing):

- Node: CNC Milling & Turning

- Description: Critical components like the blade hub, shafts, gears, and precision feed mechanisms undergo CNC (Computer Numerical Control) machining. This highly automated process ensures incredibly tight tolerances (e.g., ±0.01mm) and complex geometries, which are vital for the smooth, precise operation of the frozen meat slicer. Blades themselves are precision-ground for optimal sharpness and longevity.

- Welding & Assembly of Frame:

- Node: Robotic/TIG Welding & Frame Assembly

- Description: Skilled technicians, often augmented by robotic welding systems, perform TIG (Tungsten Inert Gas) welding for strong, clean, and food-safe joints. The main frame and structural components are assembled, ensuring rigidity and stability. All welds are meticulously inspected for integrity and smoothness.

- Surface Treatment & Polishing:

- Node: Polishing & Sanitization Preparation

- Description: All food contact surfaces are carefully polished to a mirror finish, eliminating microscopic pores where bacteria could harbor. This step is critical for hygiene and ease of cleaning, ensuring compliance with FDA and other food safety regulations. Passivation might also be applied to enhance corrosion resistance.

- Electrical & Control System Integration:

- Node: Wiring & PLC Programming

- Description: The electrical cabinet is assembled, and high-quality wiring is routed. The PLC (Programmable Logic Controller) is programmed, and HMI (Human-Machine Interface) touchscreens are integrated, providing intuitive control and monitoring capabilities. All wiring conforms to international electrical safety standards (e.g., IEC).

- Pre-Assembly & Testing:

- Node: Functional Test & Calibration

- Description: Sub-assemblies are tested individually before final integration. This includes motor function, gear engagement, and sensor accuracy. Calibration of the slicing mechanism ensures precise thickness control.

- Final Assembly & Comprehensive Quality Control (QC):

- Node: Final Assembly & Comprehensive QC

- Description: All major components are assembled. The machine then undergoes comprehensive testing, including continuous operation tests under various load conditions, noise level checks, vibration analysis, and a thorough performance evaluation using actual frozen meat samples. All safety features are checked multiple times. This phase ensures the machine meets stated specifications and our rigorous internal quality standards, which often exceed ISO 9001 requirements. Lifespan is projected through stress tests and material fatigue analysis.

- Packaging & Shipping Preparation:

- Node: Cleaning & Secure Packaging

- Description: The machine is thoroughly cleaned, sanitized, and then securely packaged in robust, export-grade crates (often wooden with internal bracing) to prevent damage during transit to any global destination.

This detailed process ensures that every Frozen meat slicing (meat chunks) machine from YC Meat Mech, a truly commercial frozen meat slicer, is built to last, perform reliably, and uphold the highest standards of food safety. Our machines are designed for demanding industries like meat processing plants, large catering facilities, and central kitchens, where attributes like energy efficiency (optimized motor and blade design), minimal maintenance (robust components), and longevity (high-grade materials, precision engineering) are critical.

Real-World Application Cases and Success Stories

The impact of a high-performance frozen meat slicer is best illustrated through its successful deployment in various operational contexts. While specific client names remain confidential due to privacy agreements, the scenarios below highlight the tangible benefits experienced by businesses adopting YC Meat Mech's Frozen meat slicing (meat chunks) machine:

- Case 1: Large-Scale Meat Processing Plant (China)

- Challenge: A major meat processor faced bottlenecks in their frozen beef and lamb slicing operations, relying on older, less efficient machines and manual labor for irregular cuts. They needed to increase throughput while maintaining consistent slice thickness for their shabu-shabu product line.

- Solution: Implemented two customized YC Meat Mech commercial frozen meat slicer units. These machines were integrated with an automated conveyor system, allowing for continuous feeding of frozen meat blocks.

- Outcome: Production capacity increased by over 150%, reducing labor costs by 40%. The consistency of slice thickness (0.8mm) improved product appeal and reduced waste, leading to a significant increase in customer satisfaction and market share for their shabu-shabu products. The robust design and easy cleaning process also enhanced their food safety compliance.

- Case 2: International Restaurant Chain (Southeast Asia)

- Challenge: A popular hot pot restaurant chain with multiple branches struggled with inconsistent meat slice quality and slow preparation times, especially during peak hours. Manually slicing often led to varied portion sizes and employee fatigue.

- Solution: Each branch was equipped with a compact, yet powerful meat slicer for frozen meat designed for continuous use in a busy kitchen environment. The machines were specifically chosen for their ease of operation and quick-change blade features.

- Outcome: Slicing efficiency improved dramatically, allowing chefs to focus on cooking. Consistent slice thickness ensured even cooking and uniform portion sizes, enhancing the dining experience. Employee satisfaction improved due to reduced physical strain. The machines proved to be extremely reliable, requiring minimal maintenance.

- Case 3: Frozen Food Manufacturer (Europe)

- Challenge: A manufacturer of frozen ready meals required precise, uniform chunks of chicken and pork for their prepared dishes. Existing equipment produced irregular pieces, leading to quality control issues and increased ingredient waste.

- Solution: A specialized YC Meat Mech Frozen meat slicing (meat chunks) machine was provided, configured with a custom dicing attachment and programmable logic controller (PLC) to achieve exact chunk dimensions (e.g., 20mm x 20mm x 20mm).

- Outcome: Achieved nearly perfect uniformity in meat chunks, significantly improving the visual appeal and cooking consistency of their ready meals. Material waste was reduced by 15%, and the overall efficiency of the production line improved, contributing to higher profitability. The machine's SUS316 food-grade stainless steel construction also met stringent European food safety standards.

These examples underscore the transformative potential of investing in a high-quality frozen food slicer. Beyond mere cutting, these machines become integral components of a streamlined, hygienic, and profitable food production ecosystem.

Frequently Asked Questions (FAQ) about Frozen Meat Slicers

To further enhance understanding and address common inquiries, here's a comprehensive FAQ section regarding the Frozen meat slicing (meat chunks) machine and frozen meat slicer technology:

- Q1: What materials are typically used for the construction of a commercial frozen meat slicer, and why?

- A1: High-quality commercial frozen meat slicers are primarily constructed from Food-Grade Stainless Steel, specifically SUS304 or SUS316. SUS304 is widely used for its excellent corrosion resistance and hygiene properties, while SUS316 is often chosen for parts exposed to more corrosive environments or requiring even higher durability due to its added molybdenum content. These materials are non-reactive, easy to clean, and comply with strict food safety standards like FDA, preventing contamination and ensuring a long service life.

- Q2: How does a frozen meat slicer achieve precise slice thickness, and what is the typical range?

- A2: Precision is achieved through a combination of a robust feeding mechanism (often hydraulic or servo-motor driven), a sharp, durable blade, and an advanced control system (PLC). The feeding mechanism ensures consistent pressure and movement of the meat block towards the blade. The PLC allows for precise, stepless adjustment of the slice thickness, typically ranging from 0.5 mm (for shabu-shabu) up to 100 mm (for larger chunks or dices), offering significant versatility.

- Q3: What are the key maintenance requirements for a frozen food slicer?

- A3: Regular maintenance is crucial for optimal performance and longevity. Key tasks include daily cleaning and sanitization of all food-contact surfaces, regular inspection and sharpening/replacement of the blade, checking and lubricating moving parts (as per manufacturer guidelines), inspecting electrical connections, and verifying the integrity of safety mechanisms. Using food-grade lubricants and following the manufacturer’s schedule for preventative maintenance is highly recommended.

- Q4: Can a frozen meat slicer cut bones or semi-frozen meat?

- A4: A dedicated frozen meat slicer is specifically designed for cutting solid, bone-free frozen meat blocks (typically -18°C to -4°C). Attempting to cut meat with bones can severely damage the blade and internal components, voiding warranties and posing a safety risk. Similarly, semi-frozen or thawed meat may not yield clean, consistent slices due to its softer texture, potentially leading to smearing or tearing instead of precise cuts. Always ensure the meat is fully frozen and bone-free.

- Q5: What safety features should I look for in a commercial frozen meat slicer?

- A5: Essential safety features include multiple emergency stop buttons strategically placed, safety interlocks on all access panels and covers (preventing operation when open), overload protection for the motor, blade guards, and a secure meat clamp mechanism. Some advanced models also include sensors to detect operator proximity or irregularities in feeding, immediately halting operation to prevent accidents. Compliance with international safety standards (e.g., CE, UL) is also a strong indicator.

- Q6: What is the typical lifespan of a high-quality frozen meat slicing machine, and what impacts it?

- A6: A well-maintained, high-quality commercial frozen meat slicer built with premium materials (like SUS304/316 stainless steel and robust mechanical components) can have an operational lifespan exceeding 10-15 years, often longer for the main frame. Factors impacting lifespan include adherence to maintenance schedules, quality of daily cleaning, operating environment conditions (temperature, humidity), usage intensity, and the quality of replacement parts. YC Meat Mech designs its machines for extended durability, minimizing wear and tear.

- Q7: What is the typical delivery period and warranty for these machines?

- A7: The delivery period for a standard Frozen meat slicing (meat chunks) machine typically ranges from 4-8 weeks, depending on current production schedules and customization requirements. Custom-built machines may require longer. YC Meat Mech provides a standard warranty of 12 to 24 months, covering manufacturing defects and major components. This warranty includes parts replacement and technical support. Extended warranties and comprehensive service contracts are often available for continuous operational assurance. We also ensure readily available spare parts for the entire lifespan of the machine.

Commitment to Trustworthiness: Certifications, Support, and Quality Assurance

At YC Meat Mech, trustworthiness is not just a promise; it's ingrained in every stage of our operations, from design and manufacturing to after-sales support. Our commitment to quality and customer satisfaction is validated through several key aspects:

- Industry Certifications: Our manufacturing processes adhere to stringent international standards. We are ISO 9001 certified, ensuring a robust quality management system across all production phases. Furthermore, our frozen meat slicer products are designed with materials and processes that comply with global food safety regulations, including FDA guidelines for food contact surfaces and CE standards for European market access, affirming their safety and reliability.

- Proven Experience: With over two decades of experience in designing and manufacturing food processing machinery, YC Meat Mech has delivered thousands of units globally, serving a diverse clientele from small restaurants to large industrial food plants. This extensive experience translates into deep industry knowledge and refined product design.

- Comprehensive Warranty and Support: We stand behind our Frozen meat slicing (meat chunks) machine with a comprehensive warranty (typically 12-24 months), covering parts and ensuring reliable operation. Our dedicated technical support team is available for remote diagnostics, troubleshooting, and providing expert guidance, minimizing downtime and maximizing productivity for our clients.

- Availability of Spare Parts: We maintain a comprehensive inventory of genuine spare parts, ensuring prompt availability for routine maintenance or unexpected repairs. This commitment to long-term support guarantees the sustained performance and longevity of your commercial frozen meat slicer investment.

- Customer-Centric Approach: Our success is built on strong client relationships. We prioritize understanding individual client needs, offering tailored solutions, and providing continuous support. Customer feedback is actively sought and integrated into our product development cycle, leading to continuous improvement.

In conclusion, the modern frozen meat slicer is far more than a simple kitchen appliance; it is a sophisticated piece of industrial equipment engineered to meet the rigorous demands of the contemporary food processing industry. From enhancing operational efficiency and ensuring unparalleled product consistency to upholding the highest standards of food safety, machines like YC Meat Mech’s Frozen meat slicing (meat chunks) machine represent a critical investment for businesses aiming for excellence. By understanding the intricate details of their design, manufacturing processes, and the comprehensive support structures behind them, businesses can make informed decisions that drive profitability and sustainable growth.

For further insights into meat processing technologies and industry best practices, we recommend exploring:

- Meat+Poultry Magazine - Supplier & Equipment Trends (Example of industry trade publication)

- Food Processing Magazine - Automation and Hygiene in Meat Processing (Example of academic or professional journal relevant to the topic)

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang|Vacuum Processing,Stainless Steel ConstructionNewsAug.09,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Processing, Stainless Steel ConstructionNewsAug.09,2025

-

Vacuum Bowl Cutter ZKZB-125: Hebei Yuanchang Food Mechanism | Vacuum Processing, 304 Stainless SteelNewsAug.09,2025

-

Vacuum Bowl Cutter ZKB-125-Hebei Yuanchang|Vacuum Processing&Stainless Steel ConstructionNewsAug.09,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang|Vacuum Processing, Meat EquipmentNewsAug.08,2025