- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

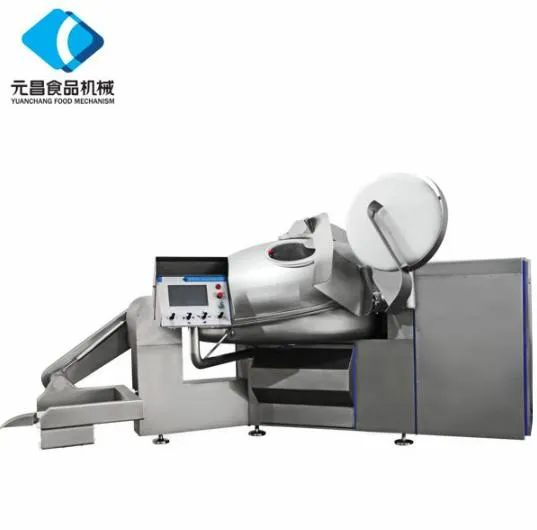

Premium Jerky Processing Equipment for Efficient Beef Jerky Production High-Quality Beef Jerky Making Equipment

- Introduction: The Evolution of Jerky Processing Equipment

- Market Expansion and Statistical Overview

- Technical Innovations in Beef Jerky Processing Equipment

- Comparative Analysis of Leading Manufacturers

- Tailored Solutions to Meet Industry Demands

- Practical Applications and Success Cases

- Future Outlook: Trends in Jerky Processing Equipment

(jerky processing equipment)

The Evolution of Jerky Processing Equipment

Jerky processing equipment has undergone significant transformation over the past few decades, aligning with the increasing global demand for high-quality, safe, and diverse jerky products. Manufacturers and food processors now rely on highly automated systems that ensure consistency, hygiene, and scale. Early equipment focused primarily on manual drying and slicing, but advancements have ushered in fully integrated solutions capable of handling every stage—cutting, marinating, drying, and packaging. The deployment of modern beef jerky processing equipment

has not only improved production rates but has redefined safety and traceability in meat snack manufacturing. This growth parallels consumer trends favoring protein-rich and convenient foods, propelling technological development across processing lines.

Market Expansion and Statistical Overview

The global jerky market is expanding rapidly, with projections indicating a compound annual growth rate (CAGR) near 7% from 2022 to 2030. North America dominates the market, accounting for over 45% of global consumption, while Asia-Pacific regions show the fastest growth. According to a 2023 industry report, commercial beef jerky processing equipment sales reached USD 1.8 billion worldwide. Automation adoption rates among large-scale plants surpassed 68% in the last five years, largely due to rising labor costs and the need for consistent product quality.

Consumer preferences have shifted toward low-sugar, preservative-free jerky, demanding flexible equipment that can handle a variety of formulations without cross-contamination. The integration of IoT technologies in jerky processing lines enables real-time monitoring and predictive maintenance, reducing downtime by as much as 30%.

Technical Innovations in Beef Jerky Processing Equipment

Advancements in beef jerky making equipment are redefining what food processors can achieve. Key innovations include enhanced dehydration technology using energy-efficient heat pumps, integrated marinading and tumbling systems, and computer-controlled slicing mechanisms. The latest machines feature touch-screen PLC interfaces, automated recipe management, and self-cleaning systems meeting stringent hygienic standards.

Sophisticated airflow designs ensure uniform moisture removal, which is crucial for food safety and taste consistency. Adjustable drying parameters allow processors to fine-tune the texture—ranging from soft and chewy to extra dry—based on target market preferences. Furthermore, advanced vacuum packaging technology maintains product freshness and shelf stability, extending product life by up to 50% compared to traditional methods.

| Feature | Standard Model (Legacy) | Modern Automated Model |

|---|---|---|

| Energy Use (kWh/batch) | 95 | 67 (↓29%) |

| Batch Capacity (kg) | 120 | 250 |

| Recipe Changeover Time (min) | 55 | 15 |

| Automated Cleaning Cycle | No | Yes |

| IoT Connectivity | No | Yes |

| Operator Requirement | 4 persons | 1 person |

Comparative Analysis of Leading Manufacturers

Choosing the right partner for jerky processing equipment is critical for plant efficiency and output quality. Global leaders include JBT Corporation, Provisur Technologies, Marel, and GEA Group, each offering specialized beef jerky processing equipment tailored for diverse scales and applications.

For instance, Marel emphasizes modular solutions and high throughput, while GEA Group is known for hybrid drying technology optimized for lower energy consumption. JBT Corporation integrates advanced food safety features, and Provisur focuses on versatile machinery capable of handling both meat and alternative protein jerky.

| Manufacturer | Key Strength | Energy Efficiency | Global Support | Customizability | Avg. Throughput (kg/hr) |

|---|---|---|---|---|---|

| Marel | Automation, Modularity | ★★★★★ | Global | High | 700 |

| GEA Group | Hybrid Drying Technology | ★★★★★ | Global | Medium | 600 |

| JBT Corporation | Food Safety, Integration | ★★★★☆ | Global | High | 650 |

| Provisur Technologies | Versatility | ★★★☆☆ | Regional | Medium | 550 |

The evaluation criteria include not just performance metrics but also after-sales support and adaptability to evolving food safety regulations.

Tailored Solutions to Meet Industry Demands

To address varying business needs, manufacturers provide configurable jerky processing equipment platforms. Start-ups may opt for compact, entry-level machines with step-by-step automation, while industrial-scale processors demand high-throughput lines with integrated ingredient dosing, vision inspection, and automated packaging.

Custom builds often factor in available plant footprint, desired product texture, seasoning distribution, and allergen management. For example, one North American contract packer implemented a modular beef jerky making equipment line that enabled a 40% reduction in labor hours and an 18% increase in yield within the first year.

Analytics-driven maintenance schedules—which harness data from integrated sensors—lower the risk of unscheduled downtime and optimize spare parts management. This holistic approach translates to greater ROI across the jerky supply chain.

Practical Applications and Success Cases

Leading jerky brands employ advanced processing equipment to maintain competitive advantage. One U.S. beef jerky producer, deploying a fully automated line, saw defective batch reductions from 3.5% to 0.7%, while doubling production volume in 18 months. Key enablers were hands-free marinating systems and continuous-flow dryers equipped with real-time humidity controls.

In another case, an Asian snacks company leveraged modular jerky processing solutions to launch four new flavor SKUs within one quarter. Automatic recipe switching, allergen segregation features, and high cycle-rate slicers made it possible to rapidly scale up while minimizing cross-contamination risks.

These successes illustrate how the careful selection and implementation of jerky processing equipment can unlock operational efficiencies, product innovation, and agile response to consumer trends.

Future Outlook: Trends in Jerky Processing Equipment

With the market expected to surpass USD 8.2 billion by 2032, manufacturers of jerky processing equipment are prioritizing sustainability, digitalization, and flexibility. Demand is rising for lines with energy recovery, minimal water usage, and recyclability of packaging materials. Predictive data analytics and machine-learning based controls empower processors to proactively fine-tune every stage, from slicing consistency to final packaging integrity.

As consumer tastes evolve and regulations become more stringent, the next generation of beef jerky processing equipment will center on adaptable designs, traceability, and integration within broader food processing ecosystems. Embracing these trends will be crucial for any producer aiming to thrive amid rising global competition and heightened consumer expectations.

(jerky processing equipment)

FAQS on jerky processing equipment

Q: What is jerky processing equipment?

A: Jerky processing equipment refers to machines used to slice, marinate, dry, and package meats for making jerky. They help automate and standardize the jerky production process. This ensures consistency and efficiency in jerky manufacturing.Q: What types of beef jerky processing equipment are essential in a production line?

A: Key equipment includes meat slicers, tumblers for marinating, dehydrators or ovens for drying, and packaging machines. Each stage ensures quality and food safety. Automated lines can significantly increase output.Q: Can I use beef jerky making equipment for other meats?

A: Yes, most jerky processing equipment can process a variety of meats like chicken, turkey, or pork. The settings may need to be adjusted for different meats. Always follow manufacturer guidelines for optimal results.Q: How does jerky processing equipment improve production efficiency?

A: Automated equipment increases speed and cuts down on manual labor. It also standardizes product quality and helps reduce production waste. This results in cost savings and consistent jerky output.Q: What should I consider when purchasing beef jerky processing equipment?

A: Consider production capacity, equipment material, energy efficiency, and sanitary features. Check if the equipment meets food safety standards and your business scale. After-sales support and warranty are also important factors.-

Premium Dog Sausage Food – Healthy Dog Food Sausage in Convenient Dog Trays for FoodNewsJun.24,2025

-

Best Mixer Grinder with Food Processor – Powerful Meat Grinder for Home UseNewsJun.10,2025

-

Meat Grinder and Sausage Maker - Best Commercial Sausage Maker for Home and Business UseNewsJun.10,2025

-

Premium Frozen Meat Slicer High Precision CuttingNewsJun.09,2025

-

High-Efficiency Sausage Processing Machine for Quality OutputsNewsJun.09,2025