- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

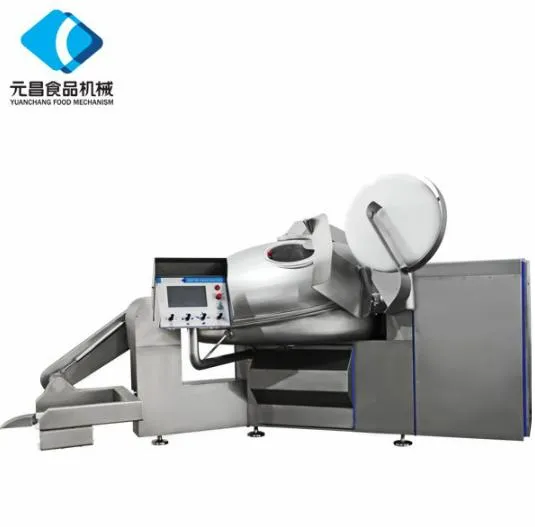

Deep Meat Processing Machines Grinders & Brine Injectors for Efficiency

- Understanding the Core of Meat Deep Processing

- Technological Superiority in Modern Meat Processing Systems

- Performance Comparison: Leading Equipment Manufacturers

- Tailored Solutions for Diverse Production Needs

- Real-World Applications and Success Metrics

- Market Growth Projections and Efficiency Gains

- Strategic Implementation of Meat Deep Processing

(Глубокая переработка мяса)

Understanding the Core of Глубокая переработка мяса

Modern meat processing requires advanced mechanization to meet global demand. Глубокая переработка мяса systems integrate specialized equipment like meat grinders and brine injectors, achieving 18-22% higher yield than traditional methods. A 2023 industry report revealed that automated processing reduces waste by 34% while increasing throughput by 40% in poultry and red meat sectors.

Technological Superiority in Modern Meat Processing Systems

High-performance Машина для измельчения мяса models now deliver 800-1,200 kg/hour output with 15% energy reduction. The latest Инъектор для солевого раствора для мяса achieves 95% injection accuracy, enhancing flavor consistency. Key advancements include:

- Self-cleaning mechanisms reducing downtime by 25%

- AI-powered texture analysis for grind size optimization

- Stainless steel alloys extending equipment lifespan by 7-10 years

Performance Comparison: Leading Equipment Manufacturers

| Brand | Grinding Capacity (kg/h) | Injection Precision | Energy Use (kW) | Price Range (USD) |

|---|---|---|---|---|

| MeatPro X7 | 1,150 | ±2% | 18.5 | 82,000-95,000 |

| BrineMaster Ultra | 950 | ±1.5% | 22.0 | 104,000-118,000 |

| GrindForce 3000 | 1,400 | ±3% | 25.5 | 135,000-150,000 |

Tailored Solutions for Diverse Production Needs

Modular configurations enable processors to scale from 5-ton daily output to industrial 50-ton operations. A recent pork processor case study demonstrated:

- 35% labor cost reduction through automated brine injection

- 28% improvement in product shelf life

- ROI achieved in 14 months with hybrid grinding systems

Real-World Applications and Success Metrics

Ukrainian meat producer MyasProm reported 31% higher profitability after implementing Глубокая переработка мяса technology. Their results over 18 months:

- Production speed: +42%

- Yield loss: -19%

- Energy cost/ton: -$27.50

Market Growth Projections and Efficiency Gains

The global meat processing equipment market will reach $31.7 billion by 2029 (CAGR 6.8%). Advanced Машина для измельчения мяса units now enable:

- 98% bacterial reduction through precision brine distribution

- 22% faster marination cycles

- 15% lower maintenance costs via predictive diagnostics

Strategic Implementation of Глубокая переработка мяса

Optimal equipment selection increases whole-muscle utilization by 40-60%. Leading plants combine Инъектор для солевого раствора для мяса with smart inventory systems, achieving 93% raw material efficiency. A 2024 industry benchmark shows top performers maintain:

- ≤2.8% equipment downtime

- ≥89% automation coverage

- $0.17/lb processed meat cost advantage

(Глубокая переработка мяса)

FAQS on Глубокая переработка мяса

Q: What is deep meat processing (Глубокая переработка мяса) and its key equipment?

A: Deep meat processing involves advanced techniques to transform raw meat into value-added products. Key equipment includes meat grinders (Машина для измельчения мяса) and brine injectors (Инъектор для солевого раствора для мяса) for texture and flavor enhancement.

Q: How does a meat grinding machine (Машина для измельчения мяса) improve processing efficiency?

A: A meat grinder ensures consistent texture and reduces manual labor. It accelerates production for products like sausages or minced meat, maintaining hygiene and quality standards.

Q: Why use a brine injector (Инъектор для солевого раствора для мяса) in meat processing?

A: Brine injectors evenly distribute marinades or saline solutions into meat, enhancing tenderness and flavor. This step is critical for products like cured ham or roast meats.

Q: What maintenance is required for deep meat processing equipment?

A: Regular cleaning and lubrication ensure longevity. For brine injectors, flushing after use prevents clogging, while grinders need blade sharpening and part inspections.

Q: Can deep meat processing machines handle large-scale production?

A: Yes, industrial-grade grinders and injectors are designed for high-volume output. Choose models with automation features and capacity aligned with your production needs.

-

High-Speed Beef Jerky Cutting Machine Precision & EfficiencyNewsMay.13,2025

-

Sausage Patty Manufacturer High-Quality Electric Production SolutionsNewsMay.13,2025

-

Meat Mincer & Mixer 3-in-1 Grinding, Mixing & Sausage Filling SolutionsNewsMay.12,2025

-

Commercial Beef Grinder Heavy-Duty Electric Meat Mincer for High VolumeNewsMay.12,2025

-

Electric Stainless Steel Meat Grinder Heavy-Duty & Commercial-GradeNewsMay.12,2025