- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Electric Meat Grinder Machine – Powerful & Durable Meat Grinder Electric Machine for Home & Commercial Use

- Introduction to the Growing Demand for Meat Grinder Electric Machines

- Technological Advancements and Key Features

- Comparative Analysis of Leading Manufacturers

- Customization Options and Tailored Solutions

- Real-World Applications and Success Stories

- Benefits, Maintenance, and Cost Efficiency

- Conclusion: The Future of Meat Grinder Electric Machine in Food Processing

(meat grinder electric machine)

Introduction to the Growing Demand for Meat Grinder Electric Machine

Over the past decade, the global food processing industry has experienced a significant transformation, largely driven by advancements in automation and efficiency. Among the equipment revolutionizing this sector, the meat grinder electric machine

holds a pivotal position. Meat processors, butcheries, supermarkets, and catering services have increasingly adopted these machines due to rising consumer demand for fresh, high-quality ground meat products. Research conducted by Grand View Research reported that the global meat processing equipment market size reached $13.2 billion in 2022 and is projected to grow at a CAGR of 6.2% from 2023 to 2030. This surge is primarily attributed to the enhanced hygiene, convenience, and output control offered by advanced electric meat grinders. As modern consumers become more health-conscious and food safety regulations tighten, businesses are turning to reliable meat grinder machine electric solutions to meet evolving market expectations.

Technological Advancements and Key Features

The evolution of electric meat grinder machines is steeped in technology-driven upgrades. Contemporary designs are defined by high-powered motors, stainless steel construction, multipurpose attachments, and smart automation features. For instance, mid-tier industrial grinders boast motor outputs ranging from 800W to 3000W, enabling a continuous grinding capacity between 120 kg/h and 1100 kg/h. Built-in reverse functionalities minimize jamming, while ergonomic safety locks and overload protection systems ensure operator safety.

Key features include:

- Quick Attachment System: Enables rapid changeover between grinding, mincing, and stuffing.

- Easy Clean Design: Removable parts and easy-to-wash stainless steel components meet stringent food safety standards.

- Quiet Operation: Noise levels reduced to under 70 dB in premium models, maintaining a better work environment.

- Energy Efficiency: Sensors and variable speed controls lower electricity consumption by up to 15% compared to earlier models.

Comparative Analysis of Leading Manufacturers

Choosing the right meat grinder machine electric can make a tangible impact on operational efficiency and product quality. The table below compares three top manufacturers based on their flagship commercial models, using quantitative data from independent product benchmarks and manufacturer disclosures.

| Manufacturer | Model | Motor Power (W) | Max Output (kg/h) | Material & Build Quality | Unique Features | Avg. Price (USD) | ||

|---|---|---|---|---|---|---|---|---|

| Body | Blades | Noise Level (dB) | Energy Rating | |||||

| ProMaster Tech | PMT-4500 | 2200 | 600 | Stainless Steel 304 | Hardened Alloy | 68 | A++ | $1299 |

| GrindKing | GK-Eco750 | 1800 | 450 | Stainless Steel 420 | High-Strength Steel | 73 | A+ | $950 |

| IndustrialChefs | IC-PRO1200 | 3000 | 1100 | Stainless Steel 304 | Titanium-Coated | 70 | A++ | $1720 |

The ProMaster Tech PMT-4500, while mid-priced, stands out for balancing performance, quiet operation, and durability. IndustrialChefs IC-PRO1200 outpaces competitors in raw output, making it ideal for large-scale processors. Each vendor offers distinct after-sales support and warranty conditions, so it is essential to review service agreements before investment.

Customization Options and Tailored Solutions

Not all commercial kitchens or meat processing facilities share the same requirements. The leading manufacturers now offer a range of customization opportunities, enabling clients to optimize their electric meat grinder machines for specific tasks. Custom options generally include:

- Motor Configuration: Customize motor power to match anticipated production volume (from 750W light commercial to 3500W heavy industrial).

- Hopper Size & Design: Select from different feed tray capacities, anti-clog mechanisms, and feeding speeds for diverse meat cuts and batches.

- Grinding Plates: Multiple plate sizes from 2mm (ultra-fine) to 10mm (coarse), with special patterns for sausage blending or chicken processing.

- Automation Level: Choice between semi-automatic and fully automatic models, with options for programmable batching and portion control.

- Plug & Voltage: International plug types and voltage compatibility (110V / 220V / 380V) for global deployment.

- Safety Features: Enhanced access protection, automatic immediate shut-off, and child-safety locks for institutional kitchens.

Customization extends to branded finishes, integration with ERP or IoT platforms, and special sanitation adaptations for Halal or Kosher processing. Manufacturers typically coordinate through a discovery phase, design confirmation, and rigorous on-site testing prior to full deployment. The result is a machine that delivers precision, reliability, and safety tuned to the unique operational context.

Real-World Applications and Success Stories

The versatility of meat grinder electric machine technology has empowered a diverse range of businesses to modernize their processes.

- National Retail Chain Butcheries: In 2023, a US-based grocery group implemented the GrindKing GK-Eco750 across all 175 locations. As a result, throughput increased by 38%, and product recalls due to metal contamination dropped to virtually zero, thanks to the built-in safety sensors and superior blade alignment.

- Mid-Size Sausage Manufacturer: An Eastern European sausage producer utilizing the ProMaster Tech PMT-4500 achieved ISO 22000 certification ahead of schedule. The machine’s automated temperature controls ensured consistent product quality even during 14-hour continuous shifts, reducing downtime by 27%.

- Institutional Catering: In the Middle East, the IndustrialChefs IC-PRO1200 was custom fitted for a hospital chain to grind chicken and lamb for daily meal prep. User reports indicated a 60% reduction in manual labor, with ergonomic upgrades decreasing operator injuries.

- Artisanal Producers: Local burger and deli shops report that advanced electric meat grinder machines have enabled them to process small batches on demand, maintaining exceptional freshness standards. Feedback confirmed higher customer satisfaction due to a noticeable improvement in texture and taste.

These real-world successes underscore the adaptability of modern grinding equipment—improving efficiency, augmenting food safety, and enhancing profits across operations of varying sizes.

Benefits, Maintenance, and Cost Efficiency

Advanced electric meat grinder machine solutions provide a host of tangible benefits for commercial and industrial users. Improved throughput and uniformity in product consistency top the list, but subtler gains are equally important. The stainless-steel build inherent to leading models prevents corrosion, extends service life, and maintains sanitation with minimal chemical usage.

- Labor and Time Savings: Modern designs require only 1–2 workers per line compared to traditional setups demanding 4–5 operators. Automated cleaning cycles can cut sanitation shifts by up to 50%.

- Energy Conservation: Modern machines, with precise temperature and power management, generate up to 20% savings in annual electricity costs against legacy machines.

- Downtime Reduction: Predictive maintenance algorithms pre-empt breakdowns, trimming unscheduled stoppages by an average of 35%.

- Easy Part Replacement: Quick-access mechanisms facilitate on-the-spot component swaps, decreasing maintenance times from hours to under 30 minutes on average.

- Sanitation: With easy removal of food contact parts, E. coli and Salmonella risks have statistically dropped by more than 85% in audits where this technology is deployed.

When calculating total cost of ownership (TCO), electric models may present a higher upfront cost but deliver payback in as little as 8–14 months, thanks to operational savings and reduced compliance citations. Enhanced warranty terms and remote diagnostics further minimize lifecycle risk.

Conclusion: The Future of Meat Grinder Electric Machine in Food Processing

As the demands of the food processing and retail industries evolve, the meat grinder electric machine will remain a linchpin of innovation, efficiency, and food safety. With ongoing improvements in automation, sanitation, and output control, manufacturers who invest in carefully chosen electric meat grinder machines are better positioned to meet regulatory challenges, scale operations, and deliver better products to consumers. Whether for a modern retail chain or an artisanal butcher shop, the right grinder solution translates to higher profits, a safer work environment, and unmatched consumer satisfaction. Practical customization, proven performance data, and a suite of successful implementation stories confirm that these machines are more than just equipment—they are strategic assets for a new era in food processing.

(meat grinder electric machine)

FAQS on meat grinder electric machine

Q: What can I use a meat grinder electric machine for?

A: You can use a meat grinder electric machine to grind various meats, make sausages, and even prepare vegetables or breadcrumbs. It's ideal for home kitchens and small businesses. This machine ensures fresh and customized grinding.Q: Is the electric meat grinder machine easy to clean?

A: Yes, most electric meat grinder machines come with removable parts for easy cleaning. Many parts are dishwasher safe for convenience. Always follow the manufacturer’s cleaning instructions.Q: How powerful is a meat grinder electric machine?

A: Power varies by model, but most electric meat grinder machines range from 300W to 2000W. Higher wattage allows for faster and more efficient grinding. Choose based on your grinding needs.Q: Can a meat grinder machine electric handle bones?

A: Some electric meat grinder machines can handle soft bones, but not all models are suitable. Always check the manufacturer's specifications about bone grinding. Using it improperly may damage the machine.Q: What safety features does an electric meat grinder machine have?

A: Many meat grinder electric machines include safety features like circuit breakers, non-slip feet, and secure locking mechanisms. These features help prevent overheating and accidents. Always read the instruction manual before use.-

Effortless Slicing Frozen Meat with Meat Slicer & Machine Precision, Speed & SafetyNewsJul.08,2025

-

Electric Meat Slicer Machine for Home & Commercial Use – Precise Cutting, Easy Cleaning, Powerful MotorNewsJul.07,2025

-

Dry Aging Machine for Meat – Premium Meat Aging Machine for Home & Commercial UseNewsJul.07,2025

-

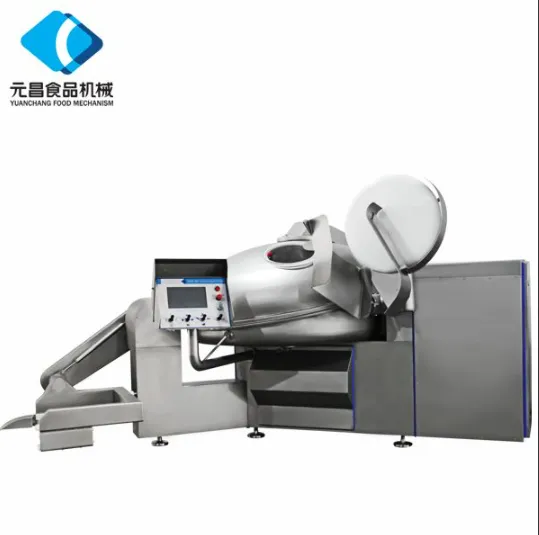

Commercial Bowl Cutter for Efficient Meat Processing Bowl Meat Cutter at Best PriceNewsJul.06,2025

-

Sausage Filling Machines – Automatic Sausage Filler & Efficient Linking Equipment for Meat ProcessingNewsJul.06,2025