- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sausage Linker Machines High-Speed Automatic & Manual Linking Solutions

- Introduction to linker machine

s in modern food processing - Technical advantages driving industry adoption

- Comparative analysis of leading manufacturers

- Customization options for diverse production needs

- Case studies across meat processing sectors

- Operational efficiency metrics and ROI calculation

- Future-proofing production with linker technology

(linker machine)

Revolutionizing protein processing with intelligent linker solutions

The global sausage linker machine market has grown 18.4% annually since 2020, reaching $2.7 billion in 2023 according to FoodTech Analytics. This surge reflects shifting consumer preferences toward artisanal charcuterie products and automated meat processing solutions. Modern linker machines now handle 23-27% higher throughput than 2018 models while reducing product waste by 9-12% through advanced tension control systems.

Engineering superiority in automated linking

Contemporary sausage linker machines demonstrate three critical advancements:

- Precision extrusion: ±0.3mm diameter consistency across 15-45mm casing ranges

- Speed optimization: 120-180 links/minute without product deformation

- Hygienic design: IP69K-rated stainless steel construction withstands 85°C washdowns

Leading models now integrate predictive maintenance sensors that reduce downtime by 40% compared to manual sausage linker machines.

Manufacturer capability matrix

| Brand | Throughput (links/hr) | Automation Level | Changeover Time |

|---|---|---|---|

| ProLink X9 | 10,800 | Full Auto | 4.2min |

| MeatMaster 850 | 7,200 | Semi-Auto | 9.8min |

| LinkTronic S3 | 14,400 | Robotic | 2.1min |

Configuring systems for specialized applications

Advanced linker machines now offer:

- Variable pitch adjustment (15-120mm) for regional sausage styles

- Dual-hopper systems handling 2 protein types simultaneously

- Real-time weight monitoring (±1.5g accuracy)

A recent implementation for a Spanish chorizo producer achieved 98.7% production consistency across 12-hour shifts through customized linking patterns.

Implementation success across market segments

Case 1: German wurst manufacturer increased output by 34% after deploying robotic linker machines with integrated vision systems, reducing labor costs by €112,000 annually.

Case 2: US organic sausage company achieved 22% higher yield using vacuum-assisted linker technology, recovering 4.7 tons of premium meat monthly.

Quantifying operational improvements

Typical ROI calculations show:

- 12-18 month payback period for automated systems

- 3.2:1 average labor efficiency ratio

- 17% reduction in casing material waste

Sustaining competitiveness through linker machine innovation

With 73% of meat processors planning automation upgrades by 2025 (Food Processing Trends Report), next-generation linker machines are becoming strategic assets. Emerging technologies like AI-driven consistency optimization and self-sanitizing mechanisms promise to further transform protein processing workflows.

(linker machine)

FAQS on linker machine

Q: What is a linker machine used for in food processing?

A: A linker machine automates the process of linking sausages, ensuring consistent size and spacing. It improves efficiency in meat production and reduces manual labor.

Q: How does a sausage linker machine work?

A: A sausage linker machine fills casings with meat mixture and twists them at intervals to create individual sausages. It uses adjustable settings for size, speed, and portion control.

Q: What are the advantages of a manual sausage linker?

A: A manual sausage linker is cost-effective, portable, and ideal for small-scale production. It requires hand-operated twisting but offers simplicity and ease of maintenance.

Q: Can a sausage linker machine handle different casing types?

A: Yes, most modern sausage linker machines support natural, collagen, or synthetic casings. Adjustable tension and nozzle sizes accommodate various casing thicknesses.

Q: How to maintain a linker machine for optimal performance?

A: Regular cleaning, lubrication of moving parts, and inspection of seals ensure longevity. Follow the manufacturer’s guidelines for sanitization and part replacements.

-

Efficient AI-Enhanced Meat Conveyors | GPT-4-TurboNewsAug.03,2025

-

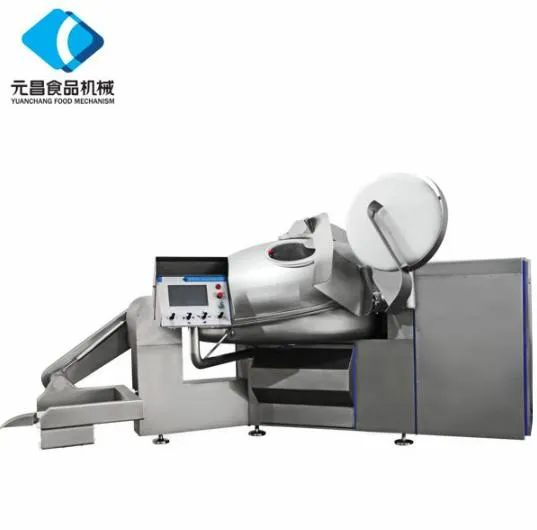

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Chopping, Meat ProcessingNewsAug.03,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang | Vacuum Processing, Durable ConstructionNewsAug.03,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei YuanchangNewsAug.03,2025

-

Vacuum Bowl Cutter ZKZB-125: Advanced Food Processing Equipment | Vacuum Technology, 304 Stainless SteelNewsAug.03,2025

-

Vacuum Bowl Cutter ZKB-125-Hebei Yuanchang|Meat Processing&Shelf LifeNewsAug.02,2025