- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- chinese_simplified

- chinese_traditional

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

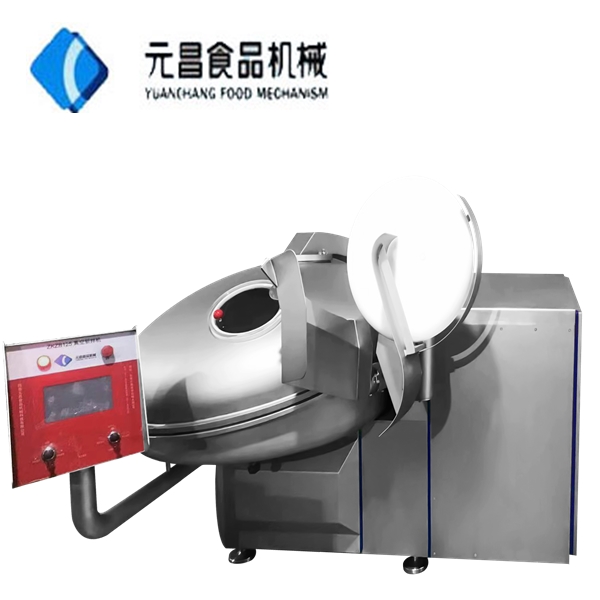

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Chopping, Stainless Steel Construction

The Vacuum Bowl Cutter ZKZB-125 represents a significant advancement in food processing technology, designed to enhance efficiency, product quality, and safety. Developed by Hebei Yuanchang Food Mechanism & Technology Co., Ltd., this machine integrates cutting-edge engineering with practical applications for both meat and pet food industries. This article explores its core features, technical specifications, and real-world benefits.

Product Overview

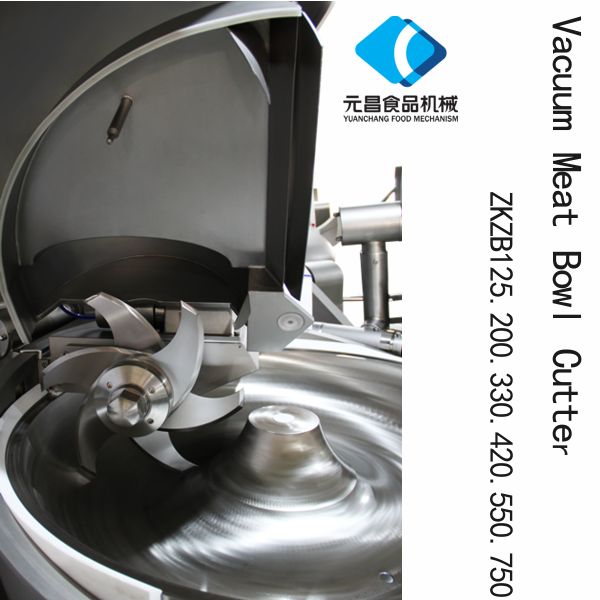

The ZKZB-125 is a vacuum-assisted bowl cutter engineered to process raw materials under controlled conditions. Its design prioritizes hygiene, durability, and performance, making it ideal for commercial kitchens, meat processing plants, and pet food manufacturers. The machine's key innovation lies in its ability to chop and mix ingredients under vacuum, minimizing oxidation and preserving product integrity.

Key Features and Advantages

The ZKZB-125 distinguishes itself through several innovative features:

- 304 Stainless Steel Construction: The main body is crafted from 304 stainless steel, ensuring corrosion resistance and compliance with food-grade safety standards. This material choice also facilitates easy cleaning and maintenance.

- Vacuum Processing System: By removing air during the chopping process, the machine prevents oxidation, preserving the color, texture, and nutritional value of ingredients. This is particularly critical for meats, where oxidation can lead to spoilage and reduced shelf life.

- Observation and Filling Holes: These design elements allow for real-time monitoring and controlled material addition, enhancing operational efficiency and reducing waste.

- Bacterial Reduction: The vacuum environment helps eliminate air-borne contaminants, reducing the risk of microbial growth and improving product safety.

- Multi-Application Flexibility: Beyond meat processing, the ZKZB-125 is suitable for pet food production, catering to the growing demand for high-quality animal feed.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | 304 Stainless Steel |

| Processing Mode | Vacuum Chopping and Mixing |

| Capacity | Varies based on application (see manufacturer guidelines) |

| Power Supply | Typically 380V/50Hz (specific details to be confirmed with the company) |

| Applications | Meat processing, pet food manufacturing |

Applications in the Food Industry

The ZKZB-125 is a versatile tool for various food processing scenarios:

- Meat Processing: Ideal for preparing ground meats, sausages, and other protein-based products. The vacuum system ensures that blood myoglobin and fat remain vibrant, enhancing the visual appeal of the final product.

- Pet Food Production: The machine’s ability to handle diverse ingredients makes it suitable for creating balanced, nutrient-rich pet food formulations.

- Hygiene-Centric Environments: Its stainless steel construction and vacuum sealing capabilities align with strict food safety regulations, making it a preferred choice for certified facilities.

Company Background: Hebei Yuanchang Food Mechanism & Technology Co., Ltd.

As a leader in food processing equipment, Hebei Yuanchang Food Mechanism & Technology Co., Ltd. has established itself as a reliable provider of innovative solutions. The company specializes in designing machinery that meets the evolving needs of the food industry. With a focus on quality and customer satisfaction, Hebei Yuanchang ensures that its products, like the ZKZB-125, adhere to international standards for safety and performance.

Industry Standards and Compliance

The ZKZB-125 aligns with industry standards for food processing equipment, emphasizing safety, efficiency, and sustainability. While specific compliance certifications are not detailed in the provided context, the machine’s design reflects adherence to principles outlined by organizations such as the National Institute of Standards and Technology (NIST). NIST plays a critical role in developing measurement standards that underpin technological advancements in manufacturing and food safety, ensuring that equipment like the ZKZB-125 meets rigorous performance benchmarks.

Conclusion

The Vacuum Bowl Cutter ZKZB-125 exemplifies the synergy between innovation and practicality in food processing. Its vacuum technology, durable construction, and adaptability make it a valuable asset for businesses seeking to enhance product quality and operational efficiency. For those in the meat and pet food industries, this machine offers a competitive edge through its ability to preserve ingredient integrity and meet stringent safety requirements.

References

National Institute of Standards and Technology (NIST). (n.d.). Retrieved from https://www.nist.gov. Note: While the specific search for "vacuum bowl cutter standards NIST" returned an error, NIST's role in establishing measurement standards for food processing equipment is widely recognized.

Hebei Yuanchang Food Mechanism & Technology Co., Ltd.. (n.d.). Retrieved from https://www.ycmeatmech.com.

-

Vacuum Bowl Cutter ZKB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Meat Processing & Pet Food EquipmentNewsJul.30,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang | Meat Processing & Pet Food EquipmentNewsJul.30,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Chopping, Meat ProcessingNewsJul.30,2025

-

Vacuum Bowl Cutter ZKZB-125-Hebei Yuanchang Food Mechanism & Technology Co., Ltd.|Vacuum Processing, Meat Pet Food EquipmentNewsJul.30,2025

-

Vacuum Bowl Cutter ZKZB-125 - Hebei Yuanchang | Vacuum Tech&Hygienic DesignNewsJul.30,2025